After my recent revelations in TimberTrader News that I once started a bushfire, I should help make amends by giving some advice on how to protect buildings from fire caused by naughty young boys like I once was!

As part of my work I go to lots of buildings that have had fires in them. On some memorable occasions I have had to attend with the fire brigade in difficult situations to help them access unstable buildings so as to put the fire out. You would imagine that a steel-framed building would perform a lot better in a fire than a timber-framed one.

It’s not the case.

For a start, it’s almost always the contents of the building that burn first, rather than the building structure itself. So it doesn’t matter what the construction, if there is

fire there will be heat!

If the worst happens and there is a fire, a timber-framed building maintains significant structural strength when heated, even while on fire. By way of contrast, steel-framed buildings “spaghettify” as soon as they heat up to the sort of temperatures experience in even a moderate building fire. Even the heaviest-duty steel portal frames end up

a twisted mess if there are lots of contents and the fire brigade can’t get it out promptly.

So, if your objective is to get out of a burning building alive then you should pray that it’s timber-framed rather than steel!

The fact that there is no particular problem with timber in a building on fire is illustrated to a degree by the bushfire standard. It does not discriminate as to the internal construction materials. You’re pretty much free to use whatever timbers you need for the main house structure.

Rather than worry about what the structure is, the main thrust of the bushfire code is to reduce the chances of a fire getting into the building in the first place.

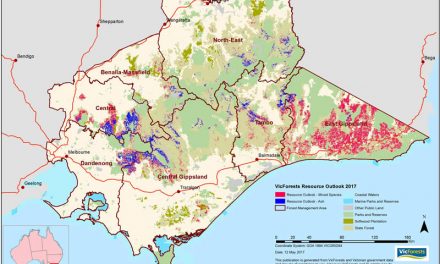

Despite the fact that I live in a bushfire-prone area, the requirements for the design for bushfire is something that I’m not that strong on. Part of the reason for that is it seems to be a movable feast. Rules have continued to evolve and change. Since the tragic Black Saturday fires in Victoria there has been four changes to the standard – and I know that my local fire authority for one has imposed their own requirements on top of that.

Whatever the case, it seems that more new buildings and extensions are being assessed as being in a bushfire affected zone. Determining what the bushfire attack level (BAL) is and then what to do about it has become an industry in itself. It’s not likely that you will have to do the assessment of the BAL. However, you may well want to keep in mind the potential need for someone to assess the BAL. You don’t want to be supplying timber for a deck on an owner’s order and then find that nobody ever determined that the deck was in a high bushfire zone and that the timbers you supplied are unsuitable. They’re going to blame you for sure, even if you delivered exactly what they asked for!

There is, however, a very good chance that you’ll be required to work out what needs to be supplied to meet the BAL requirements involved. Depending on the BAL there may be a requirement for particular timbers or detailing to external timbers. There is, of course, the Australian standard. But that is not just user-unfriendly – at over $100 it’s also expensive.

By way of contrast, the deal of the century is that you can get an excellent explanatory publication from the wood solutions website (woodsolutions.com.au) for absolutely nothing! It explains in a high level of detail and with some nice pictures just what the different requirements are for different BALs.

One notable element that can affect your designs is the requirement for a sheet metal roof in a flame zone to have a 15mm plywood lining on top of the rafters. That will have several effects upon your design:

Make sure it’s clear to you and your customer whether or not you’re supplying the ply.

There is an increase in roof weight of between 7.5 and 10 kg/m² (assuming that it’s a pine plywood).

There is a reduction in the restraint spacing to the top cord. This is because the fixing of the ply will be at 300mm spacing rather than the batten spacing of 900mm or more. This has the potential to reduce the cost of trusses.

You’re not going to need any flat metal strapping other than potentially for temporary construction stabilisation. The plywood will make a most excellent roof bracing system!

By the way, my exploits as a boy were not restricted to lighting bushfires. There was the time we set the science lab curtains on fire. There was the time we killed Mrs Cameron’s grass – a long story: the fire cracker bombs, the attempt to build a metho power rocket and the warfare with our mortal enemies from the adjoining suburb. It’s actually lucky I made it through childhood to be able to write about it!

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News.

Phone: 02 4576 1555 Email: pauldavis@timbernews.com