For instance, if the flooring contractor had provided the client with the manufacturer’s information relative to the cleaning and maintenance of the products used in the project initially, many future headaches could be avoided.

This oversight places the contractor in breach of their duty of care, exposes them to potential prosecution and makes them liable for the cost associated with any remediation required.

A well maintained and finished timber floor should never need to be cut back to bare timber. When a timber floor is installed correctly, the finishing coat is applied according to the manufacturer’s instructions and is properly maintained. There should be no reason to cut the surface back during the serviceable life of the floor. For this reason it is essential to re-apply the finishing coating before the bare wood is exposed initially.

Surface appearance changes in a floor coating generally indicate areas of considerable wear, most often attributed to foot traffic, however, poor or inappropriate cleaning and maintenance practises can result in similar wear symptoms.

Some cleaning products can damage the finish and cause unsolvable problems. For this reason it is advisable to use only the products recommended by the manufacturer. To do otherwise may negate product warranties. It is important to note here that the recommended products are usually no more expensive than supermarket brands.

There is no single solution for the care and maintenance of timber floors as coating systems fall into three broad categories – solvent-based polyurethanes, oil-based and water-based – each having a different chemical makeup and therefore, varied sensitivities to uncomplimentary cleaning products.

SOLVENT-BASED POLYURETHANE

Generally chosen for their hard-wearing nature, chemical and abrasion resistance and ease of cleaning, these coatings sparkle if swept regularly and mopped weekly with a damp mop and the manufacturer’s recommended cleaning product, or with a cap of mentholated spirits in warm water. Care should be exercised not to ‘over wet’ the floor surface.

BASED OIL

Tongue oil coatings tend to be more forgiving when movement between timber elements is likely, though less durable than their polyurethane counterparts and are generally considered more labour intensive when it comes to cleaning and maintenance. A metallised polish is often applied on a regular basis to increase durability, and this finish responds well to a regular vacuum, sweeping with an anti-static and weekly damp mopping.

WATER-BASED

Water-based floor finishes, like their counterparts, require a regular sweep with an anti-static dust mop to remove small stones and gritty particles, often followed by a thorough damp mop using only the manufacturers recommended cleaning product.

Australian standard guide ‘AS 4786.2-2005 Timber Flooring Part 2: Sanding and finishing’, states that the following points may be useful in planning maintenance procedures for polished timber floors:

a. The surface of the floor should be kept as free as practicable from grit and other abrasive material. It is recommended that dirt-trapping mats be used at all doorways as they can significantly reduce the amount of stones, grit and sand entering the area;

b. Washing and scrubbing should be avoided as timber will absorb moisture resulting in cupping, swelling and possible decay. Steam cleaning may cause damage to both the flooring and the coating system;

c. Surface treatments are available for the softer coating systems that act as a sacrificial layer. These will slowly wear away in higher traffic areas and need to be regularly applied by mopping a fresh layer over the floor; and,

d. When re-sanding or refinishing, any wax, oil or previously applied adhesive substance should be removed with appropriate solvents, which should be compatible with the application of any new finish. Anti-rejection additives may be used to minimise the severity of possible rejection.

Please note: the manufacturers of coating systems provide care and maintenance information specific to their products and specific advice on compatibility of their products with existing floor materials.

In brief, good timber floor cleaning and maintenance starts with prevention. Use external door mats to reduce the spread of sand and grit, and protective pads on chairs and table legs or furniture that require

regular movement. This will minimise and protect the floor surface from scratches. This should be followed by sweeping or vacuuming to pick up small stones and sharp particles. However, if you do use a vacuum make sure there are no loose screws or rough edges on the cleaning head.

A daily ‘whip around’ with a anti-static mop is recommended and great for keeping down the dust. Last but not least, a weekly damp mop to remove stubborn stains and scuffs – the water should be warm but not too hot and the mop well wrung out.

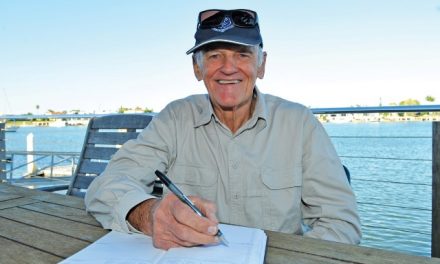

The last person to work on a floor, whether it be the installer, sander or finisher, has a duty of care to provide the person retaining their service with a copy of the manufacturer’s care and maintenance instructions, relevant to the product used on their project. The person retaining their service could be the builder or their representative, premise manager or homeowner.

It is also advisable to get your work order signed by the receiving party which acknowledges receipt of the information, just in case it is needed in the future.