George Dolezal, principal engineer at Meyer Timber, gets our new technical feature off to a good start.

Welcome to Timber Noggins. Meyer Timber is delighted to be able to present this exciting new technical feature in every second edition of TimberTrader News. My co-writer Afzal Laphir and I are both structural engineers with over 40 years combined experience specialising in timber engineering. Working for timber distributors, nailplate companies and engineered wood products (EWP) manufacturers, we have a wealth of varied experience and will be delivering topics that will answer some of your timber engineering and construction questions, and possibly ask some others as food for thought.

As a welcome feature, it makes sense to begin at the start. What information is needed to deliver an efficient engineered floor system?

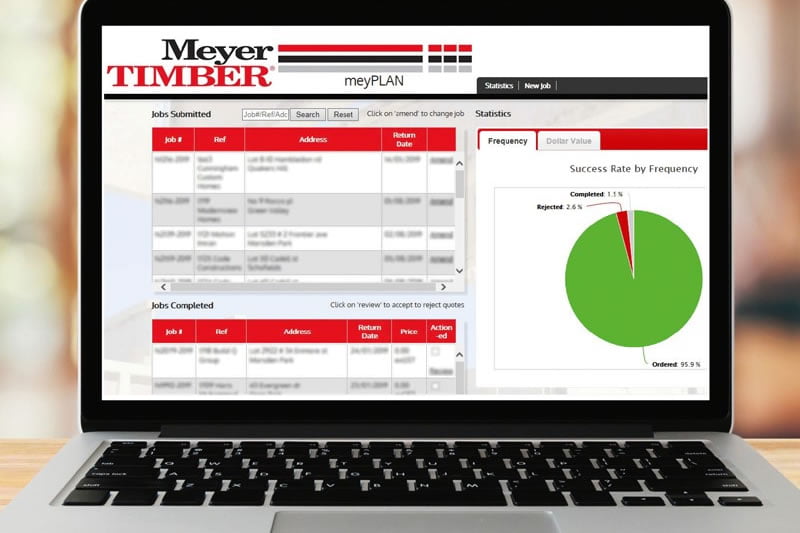

When you load up your job onto your supplier’s web portal (all major suppliers of I-joists now have a version of this) there are different ways of communicating what the builder wishes. This can be done by selection on a job-by-job basis, using standard specifications sheets, or simply putting in notes associated with that particular floor. Although not all required, the main items are:

- Final plans and engineering It’s a bit hard to deliver an efficient floor if things are going to change. Quoting a job multiple times with major revisions creates more work and confuses the builder as pricing keeps changing, so the minimum number of re-designs is preferred. Internal loadbearing walls marked on the engineering plans is helpful as it affects the design of concrete slabs.

- Joist spacing and depth Sounds obvious? Many plans show an indicative floor depth (300mm) however the builder may want a specific depth (240mm). Some engineering shows different depths across the floor plate but the builder may want a level ceiling. And floor joist spacing is very rarely specified.

- Loading and wind speed Loads are governed by Australian Standards but any changes outside this should be highlighted. This includes heavy kitchen benches, stone fireplaces and billiard tables. Wind speed is often overlooked. Floor designers need the wind classification so they can design beams under loadbearing walls etc, especially for sheet metal roof projects.

- Flooring type OSB or particleboard? Specific brand? What about special items such as fibre cement sheets in wet areas or even across the whole floor if tiled? And does the EWP supplier provide this or will the F&T/merchant do it?

- Deflection Information Be careful on this one. Builders will tell you they want a maximum deflection of 8mm, which can lead to an expensive solution. I have rarely gone to a site for excessive deflection of the floor; it is normally that the floor feels springy. Builders should not confuse deflections with dynamic performance (or bounce) and this is where education can help.

- Wet area set-downs This is becoming more popular with architectural and accessibility requirements for a level floor into these areas. Is it the whole wet area or just the shower? What wet areas are to be setdown? (WC, laundry, etc.)

- Balcony material and make-up Is it to be supplied with the floor, separately, or maybe not part of the EWP order? If supplied, the BAL rating could be needed to determine if pine or bushfire-resisting timber should be used for framing members (NSW has RFS requirements).

- Steel beam interaction I-joists can be notched into steel (possibly with web stiffeners), or supported using joist hangers (face mount or top mount onto packing plate).

- Ancillary items There are many other items that can be provided as part of a complete floor solution. These include flooring screws, flooring glue, pitching beams underneath, etc.

- The supplier designing and meeting your expectation Consistency matters. The crowded and competitive space in the market means that you would like to be able to compare apples with apples quickly and with confidence, resulting in no surprises down the track. Make sure your supplier acknowledges and understands your expectation on what things are and are not including in your quote. All of the EWP suppliers should have a design spec sheet either manual or on their plan portal. Meet with your supplier and review this as good practice!

It all looks a bit daunting from the list above. It’s already happening for frames and trusses and many items are common to floors as well. Once you get to know your regular builders and how they like to construct their houses you can often develop a floor specification sheet so all of the above is answered. It is more about the one-off floor systems that come across your desk that have individual needs. In the case of clients like owner-builders they don’t always have the experience in construction to know exactly what they need/want. By running through the above points, you can make the procurement process much easier for the client, yourself and the floor system provider.

For more information on this topic, contact George Dolezal via email at georged@meyertimber.com.au