Physical links are essential to structures, and good engineering makes all the difference. By Afzal Laphir, Principal Engineer, Meyer Timber

What does it mean to be connected? A street survey would invariably be full of associations to Linkedin, Facebook, WhatsApp or myriad other social media forums. But, if you turn the clock back to the early digital age, connections couldn’t have happened without cables and wires that required a physical link to establish them.

Unfortunately, in the context of a wall frame, there is no wireless option (wouldn’t it be nice…) It requires a ‘physical link’ in the form of fasteners and brackets to adequately tie-down a timber wall frame. Let’s look at current building practices in the domestic market, understand what gaps exist and see how we can achieve a ‘well-connected’ and compliant wall frame.

Design process

Wall frames are made up of several individual components – top plates, common studs, bottom plates, jamb studs, lintels and windowsills at openings, wind beams at voids etc. Unlike roof and floor systems, design of these wall frame components can come from different sources depending on which part of Australia one belongs to.

Engineers seldom provide specification on wall plates, studs and their connections if the building comes within the limitations of AS 1684, which is the case with most domestic houses. And even when they do specify, often it tends to be of a generic nature (“Wall frames and tie-down to AS1684”). The wall frame manufacturer then becomes the fallback option for design of prefabricated frames, where they depend on software supplied by their respective nailplating companies. These software packages may be good detailing tools but do not necessarily design all timber components and their associated connections.

With regard to frames that are built on site (stick frame), the approach to specifications is a bit hit-and-miss. On occasions, plans from architects or building designers may include specification on wall frame components. In South Australia, where stick frame is predominant, there is dependency on so-called estimators to provide design solutions. A variety of industry software and AS 1684 span tables are adopted for this purpose, without much emphasis on connections.

Gaps in the market

Like machines, the wall frames cannot function without connections being fully secured and in the case of a wall frame it means the load path must be followed through from the top plate level to the ground. Unfortunately, as discussed above, designers don’t always give the necessary attention to connections which is exacerbated by the absence of a ‘one stop shop’ software solution in the market that can satisfactorily provide tie-down specification. Hence, wall frames may be delivered to site with little or no information on connections, rendering them non-compliant and leaving specification of these to the builder or installer.

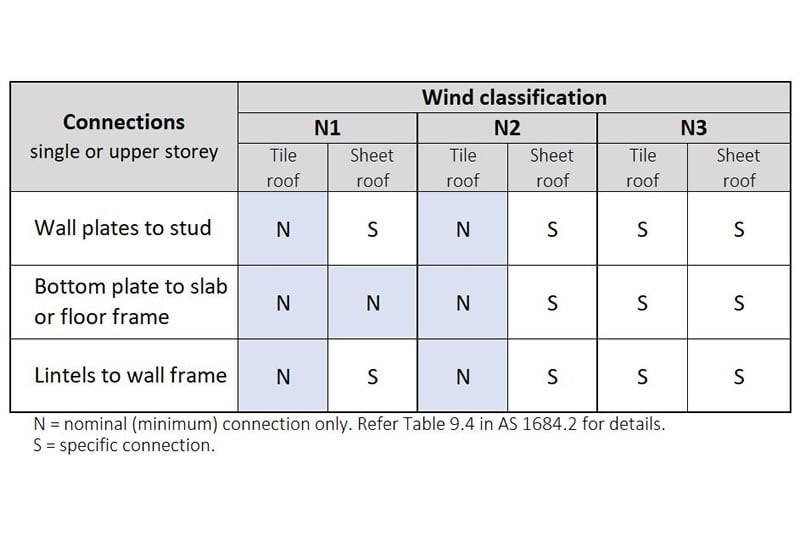

It must be noted that nominal fixing as per Table 9.4 of AS1684.2 can be used in certain cases for houses in low wind zones (N1/N2). This relates to all stud and wall plate tie–downs on houses with a tile roof, and in lower-storey frames with tile or sheet roofs. Table 1 (below) gives examples of scenarios that do not require specific connections to resist uplift.

Well-connected

Having acknowledged the dearth of simple software solutions, it becomes a huge challenge for a non-engineer to specify wall frame tie-downs. Chapter 9 in AS 1684 devotes more than 50 pages on “Fixings and Tie-down design”, which include tie-down details for wall frames and also how to assess the tie-down requirement. Although the process is clearly outlined through a flow chart in the standard (Fig 9.4), as with all processes, unless you are using it constantly it is time-consuming to achieve the final outcome and can be prone to errors. So where to next?

Multiple suppliers, including Meyer Timber, now have teams of engineers who have developed tools to offer customised solutions to wall frame manufacturers, to ensure they deliver a fully compliant wall frame to site. This can include fixings from top plate to stud, stud to bottom plate, bottom plate to slab or sub-floor, jamb studs, etc. Talk with your main suppliers or potential suppliers about what they offer – see the image at the top of this article for an example of the Meyer Design Tool.

Meeting codes

All building work must comply with the Building Code of Australia (BCA), which is contained within the National Construction Code (NCC) and provides the minimum necessary requirements for safety, health, amenity and sustainability in the design and construction of new buildings in Australia. Timber wall frames are very much part of the overall building work and its compliance is dependent on how well the minimum design requirements are met. Given the recent experiences with non-compliant products and the cladding saga, building authorities across Australia have started to tighten the screws (pardon the pun) on matters related to non-compliance. There is also an increased scrutiny on building surveyors, who are in turn responding by focusing on areas that hitherto have been given little attention. A well-connected wall frame is certainly one such area that is gaining increased focus.

So, why wait? Sometimes we still need physical links in our wireless world. Let’s get connected – engineers and manufacturers –and deal with compliance issues head-on!

The Timber Noggins series is supported by Meyer Timber. For more information on this topic, contact Afzal Laphir via email at AfzalL@meyertimber.com.au