Today only: Ultra-extreme, super fantastic advice, plus more! And only for the price of one TimberTrader News subscription.

That’s my offer to you for what you will get out of the following article: essentially, a parody of the hilarious adverts that turn up in my email from certain clothing stores, several times a week.

Their source of merriment is that their marketing model revolves around trying to convince you that you are getting the deal of the century – every, single, week.

We get it, every email has to try and create buzz.

But if I am getting “Extra savings for members – Tuesday only!” or, “20 to 50 per cent off”, on a regular basis, I start thinking that their prices are just inflated. Just call me an old, cynical engineer (and you would probably be right).

But make no mistake about it, in the case of this article, you are getting a great deal!

There is a trend for architects to design more and more ‘blade-like’ monoslope roofs. The simplicity of the thin edge profile is in response to the presence of more and more imposing and complex hip/gable combination roofs that do so well when accompanying timber trusses.

Architects particularly like the thin-roof profile in instances where the building is a series of linked pavilions.

I have been asked to do the engineering for such roofs, using both steel and stick timber. Whatever the material, the framing of the side overhang can always be tricky to achieve economically.

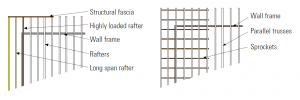

Whether it be timber or steel, it’s easy enough for small overhangs of up to 450 mm to cause the roof battens to be cantilevered. The obvious approach for larger side overhangs is to use a structural fascia that cantilevers past the last rafter, or beam, that sits over the side wall. As per the following framing plan of a corner on such a roof.

However, this approach has a few problems:

- The side eaves rafters are a full span from the structural fascia at the top of roof slope to the corresponding one at the base of the slope, which has a greater span than the common rafter;

- The structural fascia cantilevers and causes it to work even harder;

- The rafter over the wall that picks up the whole load of the side eaves is magnified by the structural fascia cantilever; and,

- The connections of the parts are highly loaded.

It’s generally all do-able, but as the overhang gets larger, the most likely solution to fit within the architectural constraints is, too commonly, steel.

However, there is an economical timber truss alternative!

If the common rafters are shallow parallel chord trusses (choose whatever flavour you like), it is possible to thread solid timber sprockets through the trusses to cantilever out to form side eaves, as per the second framing plan:

This approach has the primary benefit being that the structural work is shared between a large numbers of sprockets.

This brings the sprocket sizes and connections within the realm of light timber framing.

The sizing of the sprockets could simply be determined, taking the allowable overhang for rafters from the normal span tables at the appropriate spacing, roofing type, and wind. The only special design is for the truss over the wall line which, while generally supported on the side wall, does have a modest extra load on its overhang.

Compare this with the last steel job I designed, which had 200 deep parallel flange channel steel beams as structural fascias, plus a 200 universal beam over the wall line.

A few sticks of sprocket timber are cheaper and easier to build than steel!

Save money and build easier using timber trusses. What an offer! Was that a super special, reader only, life-changing experience or what?

And as a follow up bargain, you can buy my special release ‘If only my engineer was Paul Davis’ T-shirt or underwear merchandise for only $75. That’s 100 per cent off!

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News.

Phone: 02 4576 1555 Email: pauldavis@timbernews.com