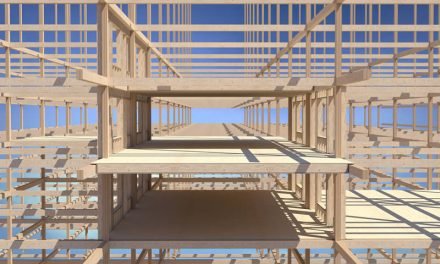

Announced in May, the high-tech sustainable timber facility will produce 60,000m3 of CLT each year, which is enough to construct the equivalent of one Forte Melbourne – Australia’s greenest apartment building – every week.

CLT is a high tech alternative to concrete, made with sustainable plantation timber.

Facts

- 12,600m2 factory

- 30 direct and 24 indirect jobs created

- $10M invested in the factory, $15M in equipment

- In excess of 60,000m3 production capacity

- Fully automated mechanical pressing facility

- One of the most technologically advanced CLT plants in the world

XLam has been manufacturing the innovative and versatile building material in New Zealand for five years and shipping it to Australia, in competition with European importers.

XLam has been assessing possible Australian sites for the facility over the last year, and has now selected the Albury Wodonga region.

Operational mid-2017, the new facility will be the sole manufacturer of CLT in Australia, and one of the most technologically advanced CLT plants worldwide.

Construction timeline

June 2016 – Construction begins

Jan 2017 – Construction completion

Mid-2017 – Factory operational

XLam CEO Gary Caulfield said the investment would be a game-changer in the Australian market.

“For the first time Australian builders will be able to choose a CLT product that is designed and made in Australia from Australian timber, meeting a significant demand in the current market,” he says. “It’ll also mean the jobs and proceeds stay in Australia, rather than going back to Europe.

What is CLT?

Cross laminated timber (CLT) is like jumbo sized plywood except that it uses timber boards rather than peeled veneers for the glued layers. CLT panels span and support loads, and connect together to provide a very strong and stable building system.

CLT is manufactured in a range of thicknesses to suit floors, internal and external walls and roofs. It may be utilised as individual components or as a complete structural system encompassing all of these.

CLT is particularly suited to compartmentalised buildings which have permanent internal walls, such as single and multi-unit residential buildings, schools, health care facilities and commercial offices.

The XLam CLT pre-fabricated building system offers dimensional precision and a very speedy assembly at the site. This allows rapid closing in of the building. Compared with other forms of construction CLT provides advantages of air-tightness, thermal insulation, internal moisture management, acoustic insulation and fire resistance.

CLT is widely used in Europe for both residential and commercial construction and is gathering strong momentum in North America. Several CLT projects are already built in Australia.

“By building this facility in Albury Wodonga, we’ll be in easy reach of Melbourne, Sydney and Canberra via the road and rail networks, and from there Australia-wide.

“We’re eager to work with the Albury Wodonga communities to build an incredible facility, and become an asset to the region.”