A custom-made solution fills a gap between budget and need.

Kiah Road Bridge in Gillieston Heights, NSW, was still functional, but ageing unevenly, with some of its hardwood deck planks crumbling but many in good working order. A total refurbishment of the bridge deck was unfeasible due to cost and the low traffic volume.

Bridge owner, South Maitland Railways, recently sought a unique solution to help extend the life of the remaining planks, while simultaneously maintaining the bridge weight limit and improving its structural integrity.

The solution was Big River Group custom-made Bridgeply planks, used as running boards fixed to the existing hardwood transverse boards along the bridge.

Bridgeply is a cross-lam structural grade plywood manufactured to AS/NZS 2269-2012 made from AFS/PEFC chain of custody certified sustainable Australian plantation pine. It provides a reliable replacement where suitable lengths of solid hardwood timber are unavailable for bridge decking. The product is envelope treated (H4) to protect against termites, fungus and environmental degradation.

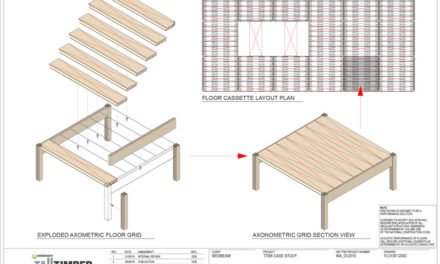

The plywood planks were created with stepped ends so they could be joined in a way that would transfer weight load from sheet to sheet as traffic passed over them.

“On top of the existing challenges of budget and weight limits, it was crucial to undertake the work as quickly as possible and ‘in traffic’, as the bridge is the only access for a handful of properties near Gillieston Heights,” said Warren Hedley, manager of South Maitland Railways Pty Ltd.

“When a bridge is closed or is load limited, the impact on the local community can be significant. Fortunately, this vital upgrade was completed within three weeks – on time and on budget,” said Hedley.

The decks were manufactured in the Grafton Mill, NSW. As the planks were 800mm wide but manufactured from 1200mm sheets, the sheet offcuts were utilised in the core of the decks to minimise waste and cost.

“Since they are made from three layers of bonded plywood, the layers on each end could be stepped so the sheets could interlock together rather than having to mitre cut them,” explained Dan Berryman, national wholesale manager, at Big River Group. This saved both time on the installation and money in the labour budget.

An economic alternative to steel or concrete, Bridgeply can be easily applied to damaged or deteriorated hardwood decking. Additionally, its lightweight composition means less machinery is required to install it.

“We chose Big River Bridgeply for its distinct adaptability to our unique problem, as well as its quality and Australian origins,” said Hedley.

For more on Bridgeply, visit www.bigrivergroup.com.au.