Wesbeam’s newest guide will expand the use of LVL.

Problems regarding a lack of experience or knowledge re specifying Laminated Veneer Lumber (LVL) have caused some designers to stick with the more familiar steel or concrete instead of turning to timber. In response, Wesbeam has produced a new publication: An Open Source Guide to the Wesbeam LVL Tall Timber Building Systems.

Available for free download, the guide has been developed by Wesbeam’s leading architectural and engineering team: authors Dr David Bylund, Wesbeam Tall Timber Building Systems team lead and Stephen Dayus, Wesbeam technical manager as well as contributors Peter Law, Wesbeam senior advisor – technical, Tom Rickerby, Wesbeam senior structural engineer and Dr Ahsan Qureshi, Wesbeam quality assurance manager. A set of highly regarded external reviewers also gave their input: Dr Andrew Dunn, CEO, TDNSW, Dr Jon Shanks, TimberEd Services, Dr Alastair Woodard, TPC Solutions, Dr Hui Jiao, senior lecturer, School of Engineering, College of Sciences and Engineering, University of Tasmania and James Fitzpatrick of Fitzpatrick + Partners.

Co-author and architect Bylund explained the motivation behind the guide: “We find many people struggle to know how to go about the preliminary design phase: choosing the correct systems and knowing what sizes, sections and spans they’re good for. This guide is intended to fill that void. When the concept design of a project is being considered, if someone has an understanding of what the LVL section sizes are and some familiarity with the material to the same degree they may have with steel or concrete, then it will help them understand the performance and the typical section sizes of a floor, beam, wall or column through that preliminary phase.”

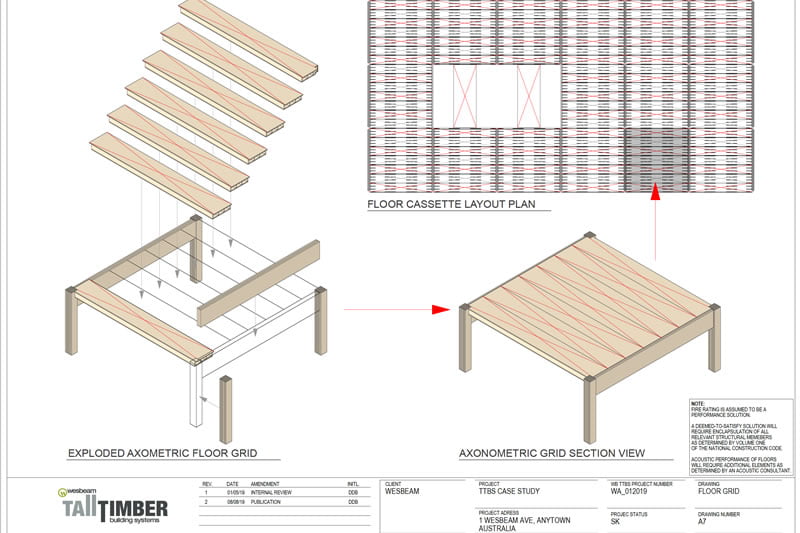

The guide summarises the design principles of mass timber using LVL, from section sizes to connection details and beyond in an attempt to build confidence in designers, engineers, prefabricators and builders who have limited experience working with LVL compared to other materials, making it easier for them to be confident to specify a timber solution.

Bylund says, “This resource is intended to fast-track that experience by giving end users some confidence and surety that if they use the span tables or load charts as intended, they’ll have a pretty good start at knowing what section sizes are typically used for an element.”

Wesbeam encourages feedback from users, and not just architects, engineers and builders. “A big part of this guide is to stimulate the fabricators to consider other aspects to their business,” says Bylund. “We have plenty of truss and frame fabricators out there doing housing-type products, but we think there’s an opportunity for some, especially in capital cities, to expand what they currently offer and this could form the basis of that expansion of offer to the market. In South Australia, we’ve already got a prefabricator who’s really coming on board based on a lot of the typical small-section elements that are in the guide and we’d hope there would be a few more rolling out across the country in due course.”

To download the guide, visit www.wesbeam.com/library/an-open-source-guide-to-the-wesbeam-lvl-tall-timbe