Freshly returned from the world’s biggest window and door event, WADIC’s Bronwyn Foord shares the news.

Fensterbau Frontale 2018 is the world’s number one international trade fair for windows, doors and façades. It attracts 800 exhibitors and thousands of visitors. The 2018 fair was held from Wednesday 18 to Saturday 21 March in Nuremberg, Germany.

WADIC members were fortunate to receive an invitation to be part of the Weinig Fensterbau Technology Tour as a Weinig and WADIC joint initiative. As General Manager, I attended with members – predominantly small to medium joinery manufacturers – and three representatives from Weinig Australia, including CEO Neil Forbes.

We visited a range of our members’ stands – both machinery and hardware – including Biesse and Felder and met lots of new brands and faces as well.

International similarities

We arrived in Vienna on the 14th and our first visit was to a company called Svoboda, meeting with the principle Alois Svoboda and his son Philipp. Svoboda employs 25 people and produces 3000-4000 windows and doors from larch and white oak each year. This company is a family-run company with father, mother and son involvement, not unlike the majority of our member companies in Australia.

Svoboda faces very familiar challenges regarding staff and business decisions about machinery and methods of manufacturing. Manufacturing methods varied from dowel joints to tilt and turn applications. This company manufactured assemblies that aligned with the UK and Australian style as well as more European influenced designs.

Once we arrived in Germany, we visited Holz Schiller GmbH, which is a German family owned (still!) company that has focused on timber products and timber trading for 370 years, with the head office located in the centre of the Bavarian forest, employing 600-plus employees. Holz Schiller have four very large automated production factories located in Germany and the Czech Republic, offering structural and laminated FSC- and PEFC-certified timber for sandwich panels, doors and windows, conservatories and terraces in red pine, spruce, red grandis, accoya and more. The majority of the machinery has been custom designed collaboratively, with over 50 Weinig machines installed and designed to fit with their specific needs.

Several other factories in Germany were visited by the group before Fensterbau. For members, this was one of the highlights. Not only to see the modes of manufacture but also to see the factory set ups, manufacturing techniques and machinery in operation, and to hear individual testimonies. Members were very interested in other aspects including different coatings and their spraying and drying set ups – and some of the hand tools not often utilised in Australian factories.

Fensterbau

It was very informative travelling with the Weinig team of Neil Forbes, Darryl Barker, Ian Staniforth and Markus Gube (Regional Sales Manager for Windows Product Unit). Weinig were very generous with their time, and get togethers!

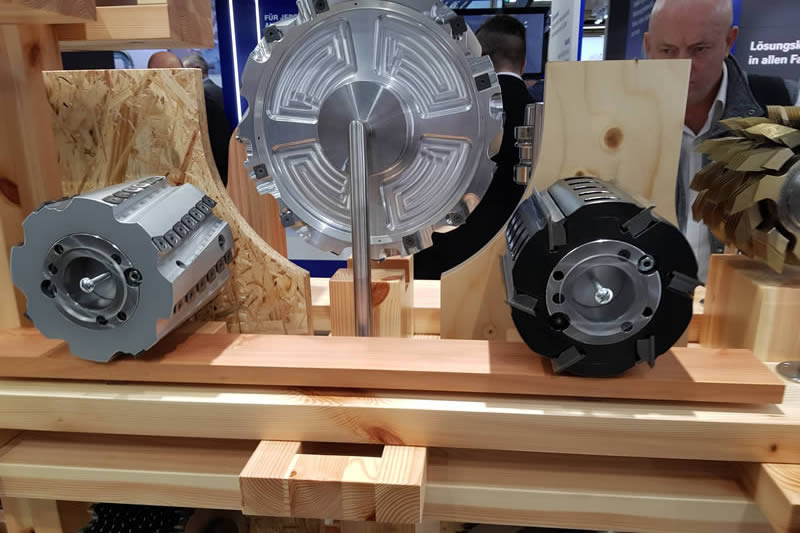

The Leitz Australian team invited us to travel with them for the first morning to the exhibition where we were met CEO Leitz Juergen Koeppel. Their display of tooling and saw blades was very impressive. Leitz are new members of WADIC and we hope to enjoy a productive relationship with the Australian team going forward.

A lesson to be learned for anyone venturing to Fensterbau is that the exhibition plans and listings are in two books. One lists the timber related machines and products separately to the rest. We only found this out on the last day which meant some exhibitors were overlooked!

WADIC member interest was focused on all brands, shapes and sizes of 5-axis CNCs, optimising and docking saws, material handling/vacuum lifts and mobile glass suckers, spraying equipment and hardware suppliers. Centor had a very impressive presence with their bifold door system and Felder attracted a lot of interest in their 5-axis CNC – we caught up with Australian team members at both stands and were able to make more connections.

When WADIC members were asked for the highlight of the Weinig tour, it was the factory visits combined with camaraderie. Members attending for their first time were introduced to more technical machines than they personally utilise in their factories, and the experiences of members who already have CNC machines was generously shared.

The conversations often turned to the day-to-day challenges experienced in everyone’s businesses and how those challenges are overcome or at times ‘suffered’. The lack of good staff was on everyone’s lips, pushing many to upgrade their factories and trying to understand the impact of taking the CNC route on their businesses and staff.

The large investment involved in CNC is easily justified by most. More difficult for owners is relying on others to run the CNC, leaving many feeling vulnerable if they are not confident to learn to program and run the machines themselves. Over the last few years WADIC has seen a dramatic growth in the uptake of CNCs and Fensterbau confirms our feeling this will continue.

WADIC will be attending the upcoming AWISA 2018, 4-7 July at the Sydney Exhibition Centre. If you wish to make a time to discuss Fensterbau or WADIC, email Bronwyn.foord@wadic.org.au