Hybrid timber/steel construction and clever software has seen Sunbury Wallframes and Trusses create a social housing success. By Jane Clark.

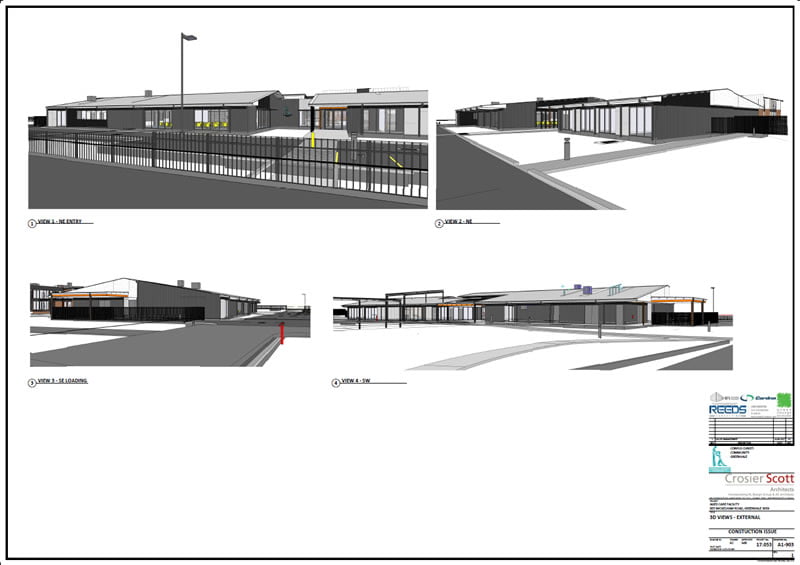

Corpus Christi is a thriving residential care facility in Greenvale, Victoria, that provides accommodation and support for marginalised older men. It first opened its doors 42 years ago, but an ever-growing demand saw it decide on a $24-million redevelopment last year.

Funding came through support from the Australian government and Villa Maria Catholic Homes. The new facility is designed to provide residents with access to state-of-the-art facilities and spacious rooms with ample storage, plus multiple lounges, dining and break out areas. The building will also incorporate a new administration wing and a fully equipped commercial kitchen.

Local company Sunbury Wallframes & Trusses won the frame and truss contract for the complex timber/steel hybrid construction. “Timber was chosen as the primary building material not only for its warmth and visual appeal, but also for its speed in construction and cost effectiveness,” says Brendan Schneider, operations manager at Sunbury.

“We also used structural steel beams as there were numerous large span beams. We’ve found that the two materials can work in harmony, and the end result is quite striking.”

Timber’s known positive effects for mental health were also a consideration. Patrick Gallagher, community director at Corpus Christi, says: “We chose timber for the redevelopment as we wanted to create a home-like environment for our residents, who are homeless men. Timber is a beautiful, natural product which has a wonderful warmth about it.”

Dealing with complexity

Corpus Christi isn’t Sunbury’s first large commercial job. “We’ve built a reputation in the area of commercial projects,” says Schneider. “Typically, we do one large commercial project a month, as well as several smaller projects.

“We don’t have a dedicated sales rep, so we rely on our reputation for delivering a highly accurate, quality product to site. It’s not just about the quality of timber we provide, but also the quality of our detailing. It’s about buildability – the fact that trusses are accurate to the last millimetre, and that we’re easy to deal with. Time is money, and if we can’t deliver, we are letting our customers down.”

It was, however, the company’s first major job since changing nailplate providers. There was a layer of complexity around the multiple ceiling planes and heights, coupled with a large amount of steel and mechanical plant spaces. Sunbury Wallframes & Trusses worked with the structural steel team, then the mechanical plan merged all elements into a master plan, using Cornerstone to import the information.

“We had moved to Multinail in February,” says Schneider, “and I questioned whether the Cornerstone software would be able to cope with the complexity of such a large commercial project. My expectations were exceeded, however – detailing this project was a breeze.

“Cornerstone allows the detailer to combine the different CAD layers/components over the top of each other. This enables the detailer to see how they’d interact and to analyse the connections between them. Being able to foresee any potential problems makes the whole project run more smoothly and time efficiently.”

Cornerstone is also able to input and export from the CAD, which allowed Sunbury to work closely with external partners such as the architects, engineers and steel contractors who all use AUTO CAD. Unlike the company’s previous software program, Cornerstone could output the 3D model to both the steel and mechanical contractors, providing detailed information on how the various components went together.

“We’ve found this ability has saved a huge amount of time and effort,” says Schneider. “It also allowed us to provide the builders and the carpentry team 3D images of the plans – which was really helpful as there were numerous different ceiling planes with different pitched heights.

“In complex commercial jobs, it’s hard for the builders to be across every single detail. We don’t mind call-outs on site, but if you can produce an accurate plan in the first place, you avoid confusion and things run far more smoothly.”

Project management

As part of the shift of nailplate providers, Sunbury also purchased Multinail Factory Management System and machinery. Although the Sunbury detailing team is highly trained and experienced, the new management system was still able to create swift and measurable improvements in their productivity.

“Multinail’s Factory Management System enables us to report back accurate production times, which makes running the project a whole lot easier,” says Schneider. “We’re also able to provide an estimated value as well as the actual costs of manufacture. This enables you to see the variances between the two.”

And there were even gains to be made in the precision of the trusses. “It’s about using a decent software program that allows a high level of accuracy,” says Schneider. “We use Multinail machinery where possible as it delivers precision outcomes and it’s well maintained. Then we have a well-honed quality process with the manufacturing team – measuring, checking and tracking throughout the whole process.

“We get most of our work through word of mouth, so continually delivering a high quality, accurate product to site is our best form of advertising.”

Despite the complexity of the ceiling construction and the transitions between materials, as well as large spans required in parts of the building, the Sunbury team was able to work through the challenges of the design without stress. The consistency of the minimum-MGP12 timbers used allowed the project to meet social housing’s stringent quality controls with ease.

Schneider had confidence in his team’s ability to deliver, but was pleasantly surprised at the ease of systems transition before such a large job – and one he feels personally invested in: “It’s been really satisfying knowing you are working on a project like this – knowing it will eventually provide a beautiful space with dignity to homeless people in the area.”

It’s a satisfaction echoed by Gallagher. “Many of the residents will be over the moon to move into the new facility, which is due to be finished next May. Their rooms will be increasing in size from 7.5m2 to around 22m2 so they will have more personal space.”

And as to the practicalities of the building process, Gallagher couldn’t be happier: “The construction process has been fantastic. In fact, we’re one month ahead of schedule, which is a rarity!”

For more information on Sunbury Wallframes and Trusses, visit www.sunburytrusses.com; for Multinail, visit multinail.com.au; and for Corpus Christi, visit corpuscc.org.au