High quality abrasives make all the difference when it comes to floor sanding, but not all are created equal. By Steven Hutchinson, Norton Abrasives

In today’s world it can be difficult to determine the authenticity of the products we use. Many products on the market claim to be one thing but end up being something else. This has certainly been the case in the hardwood flooring abrasive market.

Currently the most successful abrasives for sanding hardwood floors, particularly tough Australian hardwoods, use ceramic grain but not all ceramic grains are created equal. And not all abrasives offer a full ceramic grain coating to do the work. It’s wise to do your homework to understand what each abrasive product is made of and then see how they actually perform.

Let’s start with the grain itself. Ceramic grain isn’t necessarily a new innovation but those of us who manufacture ceramic grains are constantly innovating the design to make it perform better in specific applications. One size of ceramic grain does not fit all applications and there are many types on the market.

The first thing you should know about ceramic grain is that it is the sharpest grain offered for abrasives. The structure of the grain itself allows it to fracture under pressure leaving an ultra-sharp edge. This differs from grains such as silicon carbide and zirconia, which tend to leave an inconsistent cutting edge after fracturing. It is this ultra-sharp edge that sets the ceramic grains apart from the other grains offered in abrasives.

Secondly, ceramic grains ‘micro-fracture’ in very small increments. Similar to dropping a ceramic coffee mug and having it shatter; the ceramic grain fractures in tiny increments (slivers) that allow the overall grain to maintain its cutting ability over a longer period of time. Zirconia grains micro-fracture as well, but not nearly as small as the ceramic grains. Grains like silicon carbide and aluminium oxide ‘macro-fracture’ when they break down, causing the grain to lose its size and cutting effectiveness quickly and dramatically.

A side benefit to the very fine micro-fracturing of ceramic grains is that whatever part of the grain that does fracture off is so small that it doesn’t leave any random or deep scratches on the floor if it is picked up by the belt or disc.

Look for quality

The combination of the ultra-sharp edges and the micro-fracturing of the ceramic grain is what sets ceramic abrasives apart from any other abrasive on the market. But that is not where the differences end. Like most things in life, more is better and that stands true in abrasives as well. With the ceramic grain being so good, it makes sense that having more grain on your abrasive will make it more effective. However, there are not many abrasives on the market that offer a 100% full ceramic grain coating.

Many abrasive manufactures will blend the ceramic grain with another type of grain. The reason for this is mainly for cost control. Ceramic grains are exponentially more expensive than the other grains on the market, so in order to offer a product that most people can afford they have to blend the ceramic grain with a lower-cost grain, such as aluminium oxide or silicon carbide.

Blended grain abrasives do have their benefits in particular applications. Besides being less expensive, they can improve scratch pattern depending on the type of abrasive that is used. For the most part, though, using a 100% ceramic abrasive will always give you the best results in your hardwood floor sanding operation. The consistency of the scratch pattern and the overall durability and product life far outweigh any benefit of a blended grain product. Which leads us to the authenticity concern.

There are many ceramic products on the market today but very few are 100% ceramic. You should be careful to make sure you know which products are blended and which are not. If you are looking for an abrasive that is going to handle the toughest circumstances while giving you the smoothest scratch-free surface a 100% ceramic product is what you should be using.

A fine grind

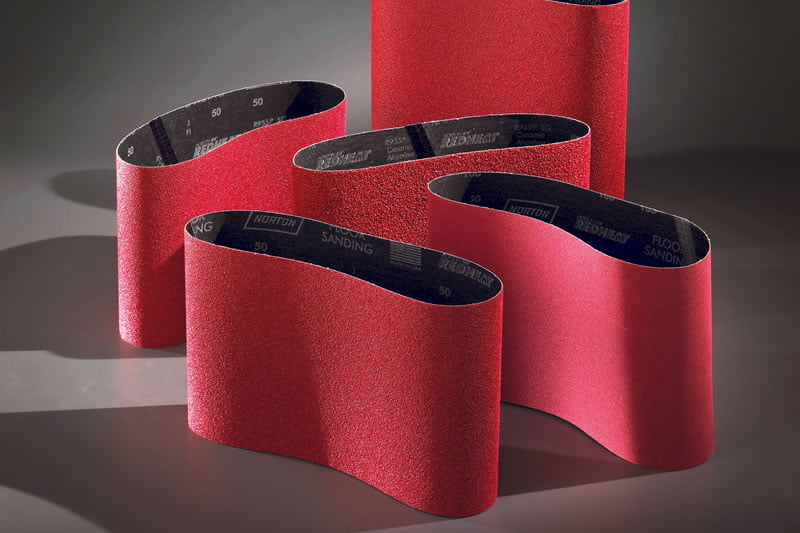

At Norton Abrasives, we’ve spent the past 15 years perfecting the best ceramic abrasives for the hardwood floor market. It all started in 2005 with the introduction of our Red Heat cloth floor belt (R955P), a 100% ceramic product utilising a grain specifically designed for lighter pressure fracturing which is ideal for hardwood flooring. However, the most important aspect of the Red Heat product is the symmetrical shape of the grain. It is this symmetrical shape that allows the Red Heat products to leave the finest, smoothest scratch pattern in the industry. All while being able to tackle the hardest species of wood or super-hard factory applied pre-finished flooring.

It wasn’t long after the launch of the cloth belts that we developed a paper (H955) and a screen (Q955) version of the Red Heat – the latter is the only product of its kind on the market. With the addition of these two pieces to the Red Heat portfolio we now have a complete line of 100% ceramic products that you can use from start to finish on any hardwood floor job.

In 2017 we launched our ceramic Blaze product to the market specifically for Sport Floors. The Blaze was designed with a different style ceramic grain that offered a little more cutting action in an effort to tackle floors with several layers of finish, such as an old gym floor. With a more open coating of grain, the Blaze product is able to cut through the thick layers of finish and resist loading to allow the product to cut fast and free. Another application where the Blaze excels is on factory applied pre-finished flooring where the same concept applies. For both large Sport Floors and residential pre-finished re-sands, the Blaze product offers superior performance.

This year our new ceramic Mesh Power hit the market. Utilising a unique net/mesh backing with our patented ceramic grain the new Mesh Power has proven to have incredible longevity in both raw wood scratch blending and between coats inter-abrasion surface prep.

While we naturally prefer our product, there are other ceramic products on the market that are also made to a high standard. Hermes Abrasives have an F-weight paper-backed product (CR116) that has a high stock removal rate and low grinding temperature, giving a uniform surface pattern without staining, as well as their economical CR456Z product with a polyester cloth backing, which is highly tear resistant and has a high belt stability.

Talk with your supplier to get the details of their product, and if you are not entirely satisfied, investigate other suppliers until you are.

We all know time is money in the hardwood floor market. It is important to know that the product you are using is the real deal and will give you the performance and results that will maximise your efforts. Relying on trusted suppliers will make your job easier, help you get it done quicker and provide the best results so that you can do more, make more and have completely satisfied customers.

For more product details, visit Norton at www.saint-gobain-abrasives.com/en-au or www.hermes.com.au

Image: Norton Abrasives Red Heat floor sanding belts