Windows and doors are still largely sold on appearance, but the new technical innovations in the sector spell opportunities for retailers, fabricators, suppliers and builders.

There are three practical factors behind decisions regarding windows and doors: how they look from the outside; how they improve the residents’ experience of the dwelling; and how they meet the physical needs of the building when it comes to soundproofing, insulation, BAL ratings, etc.

Leading companies in the industry spend enormous amounts of money, time and effort developing the best options for both separate units/parts and complete systems. They also work hard to educate builders and retail customers about their product. The result is a sector that’s thriving from both a design and an innovation standpoint – with products where a little bit of extra spending during a build can easily be in the owner’s financial interests for years to come.

Pre-fabricated window and door systems now come ready to install, with the seals and surrounds as one complete package, making life easier for builders and delivering an energy-efficient solution for the homeowner. Well-sealed and appropriately glazed systems can deliver a home that blocks out 87% of heat in summer, without touching the air conditioner.

Getting it right

“People just live with bad windows a lot of the time,” says Andrew Stewart, technical support manager at SchlegelGiesse, an international firm renowned for its seals and hardware. “They don’t know the many available types and configurations or realise there are so many variations to windows and seals. They rely on builders and designers.”

The same is largely true of doors; while customers are usually clear on what they want in the way of looks, many first home buyers in particular don’t realise how much attention they should be paying to the whole system including seals and surrounds.

“Pivot doors took off a few years ago,” says Patrick Antoine, national sales manager at Hume Doors & Timber. “They don’t have any hinges, they’re actually pivoted from the top and the bottom of the door, but that makes sealing the door a bit harder.”

Here a solution was easy for the family-owned Australian company with some 370 people on the manufacturing team at the Lansvale head office. They designed a factory-assembled unit with the door and seals all in place. “Builders love it because it’s a one-step process to install on site. Owners love it because the complete units give better soundproofing and insulation, which means a quieter home and lower power bills. And obviously it affects your Basix or Green Star rating.”

“Energy requirements have become a big driver of products,” agrees Stewart. “Pre-assembled units have multiple advantages, including accurate installation of the seals. When we test for wind and water, we see big differences in performance from the way the seals are oriented or overlapped. The jointing at the corners can have a big impact: you might go from one water performance level up to the next just by changing the way the seals are cut.”

And then there’s the choice of seals themselves. “Different seals have different compression recovery rates,” Stewart says. “If your windows are closed for a long time, when you try and open them, the basic PVC seals will stay compressed and it can be a really hard open to crack that seal.”

When closed again, they may not seal properly because they’ve lost the ‘memory’ to recover. SchlegelGiesse’s QLon range has a polyurethane foam core to counter this problem, as well as a weatherproof lining for longevity. “It’s one of the biggest sellers in the range,” Stewart says, “along with the Aquamac series, particularly AQ21. They’re suitable for timber, PVC and aluminium and are affordable, but test really well for acoustics and thermal qualities and have great compression recovery, even in different climates, giving a better seal for longer.”

Buyers definitely understand the value of seals. “Our Weatherguard entry systems are among our best sellers,” says Antoine.

Manufacturing ease

Alongside increased parts technology is an increase in customisation. Where once product ranges were kept small to increase profit margins, machinery advances mean even single unit runs can be done at a price to suit buyer and manufacturer.

“We have about 12 of the latest state-of-the-art routing machines here,” says Antoine at Hume’s head office. “Once you put a design into that system, it’s there forever. So even though it might not be in the brochure for 10 years, as long as you can show us a picture, we can find it in the system. There are thousands in there.”

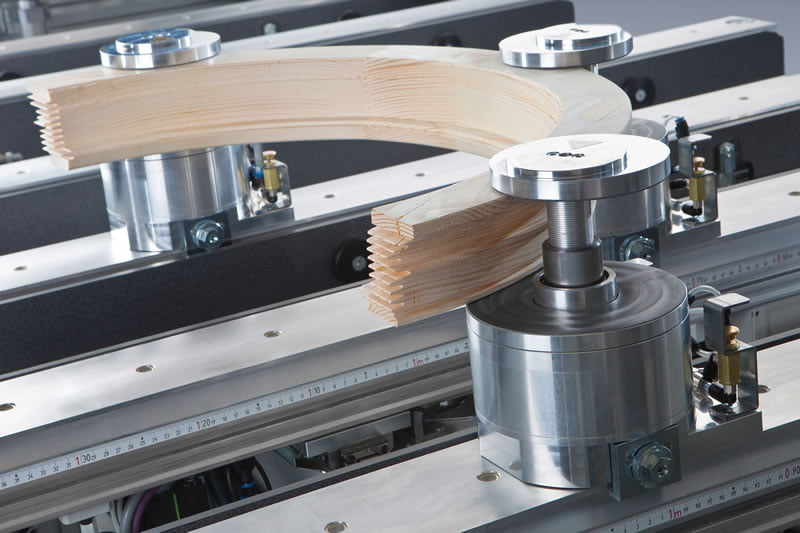

This level of customisation is only possible with the advent of sophisticated machinery that automates the joinery. One of the leading brands in Australia is Weinig, with the company’s CNC ProMaster or Conturex models able to machine and process components of any window or door design, regardless of complexity.

“Weinig is unique in that we can supply machinery for all the processes required in the manufacture of window and door components, up to assembly point,” says Neil Forbes, managing director at Weinig Australia.

Individual sashes and frames can be processed completely in a single run on machines ranging from small individual models to complex production lines.

“We work closely with the customer to help them choose the correct machine from the onset,” Forbes says. “It’s not an either/or decision: the correct choice of machine allows for economical production of standard windows in a high-capacity situation, while also offering the flexibility of one-off bespoke windows.”

Despite having multiple grinding and cutting mechanisms, the machines require nothing more complicated in the way of maintenance than other cutting equipment. “Obviously they require servicing and responsible housekeeping from the customer,” says Forbes, “But using the in-house experts for servicing keeps everything at the high level of accuracy required for such precise cuts and finishing, which is accurately repeatable as often as the customer needs.”

Weinig offers a complete solution of ripping, cross cutting, planing and profiling as standard supply from the Weinig range. “So whether it’s a CNC Weinig Conturex, Pro Master or Moulding machine, complex designs, double- or triple-glazed, insulation or fire-rated design all comes down to the ease of our programming, correct tooling solutions and stability of the machine,” Forbes says. “A complex design is programmed and components are machined as efficiently as the simple designs.

“The result is reduced labour cost and eliminating complex and costly set up times whilst providing complete flexibility in design, dimension and type of corner joint.”

Reading the trends

“The biggest changes in doors and windows have been size,” Stewart says. “Where once you were looking at a maximum of 2m, now you can easily be looking at 3m high and 4m wide. At larger sizes, you have real problems with air leakage because of the greater deflections at higher pressures. The new Euro groove systems solve much of that for aluminium systems, because they allow multi-point locking, all driven from the one central handle. We’re looking at similar solutions for timber systems.”

Some established products are increasingly popular. “The Amesbury Truth range came to us through a company acquisition,” says Stewart. “Its casement and awning operators have arms, so instead of doing lots of little winds to open the window, it’s just a few turns. You can keep the fly screen in place, with no little portholes. And if you have an awning, you can tie it into the same style of operator.”

Another new SchlegelGiesse initiative in planning is simple, Stewart says: “People call us looking for replacement seals after some sort of damage. They don’t want a whole roll, so we’ve been directing them to maintenance people and similar who can sell them a smaller piece from their stock.

“But we have thousands of products, some with specialist profiles that not many people will have on hand. So we’ve been looking at selling in smaller package sizes – 6-10m – whether through our distributors our ourselves. I hope it’s something we’ll launch this year.”

Antoine has seen the same shift to larger sizes: “For front doors in particular. Everyone wants to go big these days.”

The trend has practical advantages in meeting regulations for accessible buildings and making it easier to move bikes, prams, furniture and more in and out of the house.

“Originally a few of the builders did it because it looked good,” Antoine says, “but then everyone could see the added benefits and it’s taken off from there.”

Internal doors are changing, too. “The barn door has taken off recently,” says Antoine. “It’s generally used as a feature, say on a walk-in pantry or to mark a transition between different parts of the house, with plainer doors elsewhere.”

As a result, Hume is developing new cavity systems and self-closing tracks for barn doors, as well as a new system called the Bandit Door. “Simonds Homes approached us a year ago and said they wanted to offer what’s essentially a panic room in some builds. So we designed a door that looks like a normal door but underneath the veneer there’s a special 0.8mm-thick product from America that acts a bit like Kevlar. We’ve had it tested by Melbourne University and it’s come back around about 20 times stronger than a standard door.”

The company has an Innovation Team that includes sales staff, carpenters and ex-builders, who bring expertise from design, to marketing, to timber and ensuring FSC compliance. “We find the team might put 40 different ideas into the mix. Of those, maybe three or four go through, and of them, there might be only one that really sells well at first,” Antoine says. “But what the customer sees is that Hume is always coming up with something new. A lot of our new product comes from watching international trends, but we also work closely with our builders, retail customers and suppliers.

“Hume is a big, multi-layered company and we have several R&D teams as part of that. They take an idea and test it to see if it will work, or if the design needs practical adaptations. Sometimes only part of an idea will make it through, but it’s a part that can improve multiple other products.”

Testing product

With a series of standards for windows and doors, encompassing wind and water resistance, acoustic and thermal insulation and also BAL and fire ratings, testing is an essential part of the industry.

“Most people know SchlegelGiesse for our seals, but the testing side is also important,” says Stewart. “We provide the service for whoever needs it, they may not even be using our product.”

In the past, the company had mobile test rigs that could test product up to 2.2m high, but age and the advent of product sizes has seen them retired in favour of a static testing lab, about which Stewart says, “It’s a lot bigger. Now we can go up to 3.2m high and 4.2m wide. We offer test services to joiners and fabricators if they want to trial different seals or different hardware on their windows. It’s mostly pressure testing for wind and water, air leakage for energy ratings and the operating force – to see how easy or hard it is to close windows and doors. We can also verify seals and hardware on drawings.”

There are six levels of Non-cyclonic ratings – N1 to N6 – and then four Cyclonic ratings – C1 to C4. Products are tested for deflection and then associated ultimate pressure. “There are higher levels if you have a corner window within 1.2m of the external corner of a wall,” Stewart says, “because the increased pressures essentially try to suck the window off the wall.”

For each rating there are two water levels: Non-exposed and Exposed. Specifiers will determine what’s needed in a new build and the certifiers will check it. New products should be labelled to show the level they achieve, “So it’s easy to see if a particular product passes what’s needed. Which isn’t to say people don’t put the wrong window in the wrong opening sometimes,” admits Stewart.

It’s a complex field, and one where the main companies work closely with the industry associations, especially AGWA and WADIC to get the word out about new developments and which products are meeting what criteria.

Fire testing requires expensive furnaces and is usually managed through the CSIRO or Exova Warringtonfire.

Hume has recently released a series of BAL-rated doors for the Australian market. “Our BAL 19 and 29 doors were made to the Australian Standard,” Antoine says, “So they didn’t require testing. But for our BAL 12.5 and 40 doors, we changed the design slightly, so we had to get them tested at Exova.”

BAL-rated doors require hardwood surrounds – often merbau – and minimum 6mm toughened glass, situated high enough in the door to avoid ember attacks, among other requirements that can be hard to keep abreast of, as Hume has found.

Antoine says, “After we released our BAL brochure at the end of last year, we had builders ringing to tell us how useful it was to have all of the information on BAL ratings in one place. Previously, we had multiple documents about BAL ratings and most builders didn’t read all of them. Because there’s been so many changes in recent years, it’s very hard to stay on top of it all.”

Happily, the strong relationships between leading suppliers and manufacturers and the industry associations mean that testing information remains accessible and regularly updated, so it’s easy to have confidence.

For more, visit www.humedoors.com.au, www.schlegel.com/australasia, www.weinig.com.au, www.agwa.com.au, www.wadic.org.au