More than just openings, windows and doors are the faces and the security of our homes. And now there are more sophisticated options for them than ever before.

There’s a cliché that residential building is conservative and slow to change. Nothing disproves that as much as windows and doors, which even in the most traditional of buildings bring an incredible range of options and tech for builder, fabricator and owner.

At the most basic level, homeowners and developers want windows and doors with street appeal. Layered on top of that come concerns with safety, fire resistance, noise proofing, durability and potential for integration with Smart home systems.

All of these are opportunities for fabricators, retailers, joiners and builders to take advantage of what the manufacturers are bringing into this sector to help grow their businesses. Over the following pages we talk with leading manufacturers about what’s new in technology, manufacturing and tooling. Whether your customers are retailers, builders or homeowners, you’ll find something to add to your offer – and profits.

Sophisticated models

Windows have been making enormous strides in technology for decades now, first with soundproofing and, more recently, with high-strength fire-resistant glass for BAL-rated areas. What’s less well known are the advances being made with doors.

Solid or cavity choices have been joined with a range of composite options that take advantage of new materials to provide previously unachievable security at lower weight and cost points.

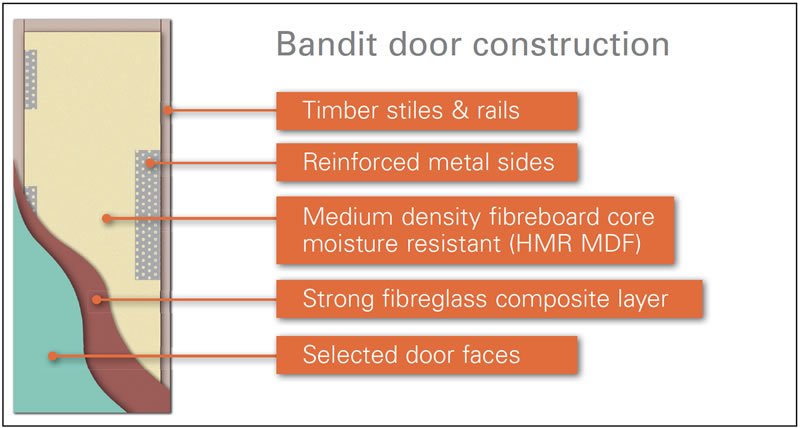

As an example, Hume Doors & Timber have added to their range of architectural and BAL-rated doors and frames with the Bandit door. This model takes the traditional high-impact metal security screen and effectively puts it ‘inside’ an attractive external door (see diagram below).

Its genesis didn’t come from standard R&D, as Ian Sengstock, marketing manager at Hume, says: “We met a fellow at an expo and he had this particular type of material that he’d been developing and was looking for opportunities for it. It’s a kevlar-like material that’s refined with fibreglass and more. He started to talk to us about the possibilities of using it in timber doors and we were really interested, so we started doing some research and prototyping, and here we are.”

The Bandit door comes with a wide range of door face options for the exterior and interior sides but, in between, layers of safety materials work together to provide a door that is extremely strong without being overly heavy or expensive.

The timber frame that goes around it has also been reinforced using similar material and metal. “A lot of technology from our steel-door framing section is incorporated into the timber, making a hybrid sort of frame,” Sengstock says. “The weak access points where doors tend to fail – whether they be the lock or the hinges – are also reinforced.”

Coming in at multiple price points dependent on finishing, the Bandit door is just as at home in social housing as in holiday homes and domestic residences. And while it’s no more difficult to install than a standard door, it significantly outperforms them. “From our testing, we’ve advertised that it’s 16 times stronger than a normal door,” says Sengstock. “In fact, the figures we’re getting are significantly higher than that, but we want to do more sampling and testing to make sure we have the fully accurate numbers and that they’re consistent in real-life applications.

“We haven’t had these doors tested for fire or noise ratings yet, but the raw sheeting that goes into them has been tested. When we test the whole package through the CSIRO, we’re confident it will perform well.

“If we hadn’t struck up that conversation, this design would never have happened!”

Style and substance

Internal doors have also had an upgrade. Hume’s Evolution Complete system, a cavity unit that comes in both timber and steel frames to suit the house structure, is one of the company’s most popular lines.

“The Evolution has been around for a while, but we saw there were ways we could improve it,” says Sengstock. “We’ve increased the strength, we’ve changed the materials so you can tile up against it in wet areas and we’ve improved the running system, so it’s nice and quiet. There’s also a quick release system to get the door off – hopefully you’ll never need to use that, but you never know.”

Like most cavity systems, the Evolution fits neatly within a standard wall. It comes with comprehensive installation instructions – so straightforward that the same model is sold successfully in the retail market for DIY builders – and can fit a wide range of door frame sizes, which makes it perfect for closing off semi-open-plan areas, helping to meet Green Star requirements when it comes to heating and cooling.

“It’s got a one-touch release system where it sits and holds itself inside the pocket when it’s fully open,” Sengstock says. “A quick press and out she pops. Pull it along a little bit and then the soft-closer takes over and grabs the door, closing it for you without slamming. Particularly in new homes, architects are using cavity pockets more and more, because they mean you get to use all your room, not leave a big space for a door to swing.”

Appearance remains a key selling point for doors. Hume stocks timber faces ranging from Australian hardwoods to popular tropicals. The frames, cavities and internal panels are usually engineered wood products (EWP), with LVL common in framing and moisture-resistant MDF internally. As Sengstock says, “The reason for choosing EWP in so many applications is the stability of the product. It lets us back all our product with a five-year warranty with confidence.

In addition to the new technologies, new style ranges are scheduled at Hume.

“We’ve got an exciting entrance range we’re just about to release for the Hamptons genre of homes that are all the rage at the moment,” says Sengstock. “You’ll see a really lovely change in street fronts as these come through.”

Smart options

Clever materials choices are increasingly being joined by Smart technology in windows and doors, whether for security or comfort. Not just convenient, these remote- or app-controlled devices mean you don’t have to worry about kids losing keys and cut out a lot of awkward reaching for insect screens and shade blinds.

“We’re working hard to get the word out on these products,” says Craig Patterson, marketing manager at Allegion (Australia), “because people can be a bit intimidated. They think they’re hard-wired or complicated or expensive and that’s actually not the case at all, they’re pretty easy to install and a great upsell to many of the customers for your average fabricator or builder.”

The Gainsborough Trilock is one of Allegion’s best-known products. Found in houses all over Australia, it has three modes: Passage with both sides unlocked; Privacy with it locked from the outside only and turn-handle exit from inside; and Deadlocked, which is locked with a key and entirely secure when you leave the property. “Last September we launched an electronic version, the Freestyle Trilock,” Patterson says. “If you can install a Trilock – which most builders and many homeowners can – then it’s just as easy to install this.”

The Freestyle Trilock can be retrofitted into existing doors and is all battery-operated, with an emergency key and back-up battery option. It has an optional Wi-Fi bridge that lets you operate and monitor the lock remotely from a phone app, and a door sensor kit that can tell you when your door is closed or open.

“The app is super user-friendly,”says Patterson. “You can set schedules or give out limited codes. If you’ve got a cleaner that comes only on Tuesday afternoons, you can set a code for 1–4pm. We have one on our house, which is for sale, so we gave a limited access code to the real estate agent so they could show people through without us being here, keeping it Covid-safe.

“It gets rid of all the complexity around having copies of keys and keeping track of the copies and worrying about them going missing. And you can control it all from your phone in real time.”

While most Freestyle Trilocks are being bought by the fabricator and builder market as a value-add on new homes, the same model is sold in Mitre 10, Natbuild and Bunnings stores, highlighting the simplicity of installation and set-up.

Allegion also distribute Schlage electronic locks, an American brand that’s designed for the DIY market and also uses battery power, so can be easily retrofitted.

“They’re great products,” Patterson says, “very well-designed keypad systems that are now also Smart. There’s the Schlage Encode, which was one of the first locks with built-in Wi-Fi so that you can connect it to your Smart systems. It works with Google Assistant and Amazon Alexa, so you don’t even need to get your phone, you can be in bed and say ‘Alexa, lock the door’. Again, you can send entry codes to the real estate agent or cleaner, and it tracks when someone uses or attempts the door. If someone tries to tamper with the lock, it sends an alert to your phone.”

The Schlage models include a range of matching modern hardware options and allow you to send guest codes by text to your visitors, making them perfect for holiday properties and Airbnbs.

Easy screens

Smart options go beyond the front door. Large windows have become a popular part of modern homes, especially servery windows leading from kitchens directly to outdoor dining areas. Enter the Brio 312, an electronic insect screen/shade screen.

“Before, the options for those sorts of windows were all mechanical,” says Patterson, “so you’d have to lean over the bench to pull it down. The Brio has a battery-powered motor that recharges via USB and uses a remote or an app to pull it down or up as needed. It’s a great little device.

“For fabricators and builders working on these types of houses and windows, it’s an easy addition that really pays off in what the house can do and people’s enjoyment of living there. It’s a good return for the small amount of work involved, without being a big extra cost for the homeowner.”

Allegion’s Brio 312 screen lifts and lowers at the touch of a button – perfect for servery windows.

Again, the installation process for the electronic product is just as easy as for the mechanical. Brio is best known for sliding and folding door hardware – French doors and conservatory windows, for example – and so a range of window systems are available that will work seamlessly with the 312.

The Brio and Gainsborough products were both developed in Australia and were made specifically for Australian standards and conditions, while the Schlage has been extensively tested under local conditions both in Australia and NZ.

Construction opportunities

At the same time as the user technologies have been improving, manufacturing machinery has reached new levels of ability in its automation. Complex CNC machines make it economical to do small bespoke runs or high-capacity production in the same plant, depending on what’s required.

Weinig is one of the leading machinery brands in Australia in this space, with an offer that can supply machinery for every process required in window and door manufacture. The brand offers two sector-leading CNC ranges, the Conturex series and the HOLZ-HER Pro-Master series. Both are able to handle complex milling and joints in extremely short processing times, with accurate clamping and a single data set controlling all production components helping to deliver exceptional precision, time after time. Complex, triple-glazed or fire-rated designs are handled with the same ease, reducing labour costs and removing the laborious and time-consuming set-ups required for a more manual joinery line.

While there is an obvious set-up cost, automation delivers equally obvious advantages, particularly at a time when we are losing a lot of industry expertise and labour costs remain high.

For specialist joiners and businesses with a joinery sideline, the 5-axis Pro-Master series delivers a large-capacity machine with a comparatively small footprint. The models have a class-leading working depth and height, making them suitable for decorative elements as well as basic cabinets and a full range of window and door components with the appropriate clamping systems installed, expanding what you can bring to your market at an attractive price point.

The Pro-Master combines precision milling with extreme acceleration and high-speed feeds of the head, plus accurate drilling and a pressure-booster for very hard surfaces, all covered by a 10-year warranty. A comprehensive basic tool magazine with short changeover times delivers a huge series of options, with the tooling sequence automatically optimised by the machine’s software. Depending on requirements, additional tool holders can be added.

Weinig’s HOLZ-HER Pro-Master 5 Axis CNC series is a one-stop joinery saw and routing machine that is particularly suited to window and door components.

The software that runs the machinery is highly advanced but doesn’t require expert levels of training for users. A comprehensive library of elements and integrated drag-and-drop design facility works on user-friendly design principles to help operators input new projects and delivers matching CNC programs, plus optimal positioning recommendations for materials and the machine’s suction cups.

A milling visualisation of the CNC program comes as a standard part of the software and can be upgraded to incorporate other aspects of the machining process, allowing designers and plant managers to preview the manufacturing process from the office.

A raft of safety and ergonomic features are installed to benefit the users, ensuring lower injury rates and therefore lower insurance costs. When added to the increased output, increased accuracy and removal of retouching time and costs, it’s easy to achieve a fast return on investment.

Weinig’s machinery portfolio is designed to work harmoniously across the ranges, with a broad set of accessories depending on your needs. The specialists on staff include experienced joiners who can help develop system solutions.

Keeping up appearances

“The main goal for timber is always to make it look as good as possible and to protect it for as long as possible,” says Stuart McLean national specifications manager for Tenaru Timber & Finishes, the national distributor of coatings brands including Sikkens. “Aesthetics and protection are the two key factors. Then there’s respecting the timber, trying not to change its appearance too much. We want to let the timber do all the talking, rather than the product.”

Concerns about maintenance have historically been a motivating factor for homeowners choosing non-timber window options – a false economy as even quality metal windows are out-performed by the vast majority of timber options when it comes to thermal and noise concerns. Choosing high-end coatings that are specifically suited to the project will give the best and longest-lasting result.

“I would always recommend people talk to us to get exactly the right information,” McLean says. “We work with both the resellers in stores and the retailers that stock our product as well and we do a lot of educating to make sure they have all the right information to pass onto the builder or the homeowner. But we’re also here for the designer or builder to talk to directly so we can be as specific as possible about what our products and systems can and can’t do.”

The product ranges on offer include oil- and water-based options, suited to the wide range of joinery choices on the market.

McLean says, “For joinery in timber doors and windows, a lot of the time the timber that’s used is softwood, so the products that go onto those timbers need to be a little bit more flexible, and a little bit more forgiving when there’s some movement in expansion or contraction – and also the obvious opening and closing. Compare that to something like a deck where it needs to be super hard as it’s getting walked on all the time. But both need that maximum protection for facing fully exposed areas.”

A recent project in Bringelly, a Sydney suburb, showed how both needs can be met with complementary products. Two coats of Sikkens Cetol Filter 7 Plus (in Pine) were used on the (many) exterior windows and doors that sit in direct sunlight. An oil-based medium-build top coat with a satin finish, it lets the natural timber grain shine through, while filtering out the sun with UV light absorbers.

Underneath, a base coat of Cetol HLSe – a low-viscosity, low-build stain – allowed maximum penetration of the timber and optimum key for the top coat. It comes in a matching colour range with the Filter 7 Plus and can be used on its own as a three-coat system, as it was here around the pool and decking. Low-build finishes help to prevent peeling and uneven weathering on hard-wearing surfaces and are easy to re-coat. For the reconditioned cedar windows, doors and uprights that receive a large amount of sunlight, the Filter 7 Plus was brush-applied to give a high-end finish that will last the test of time.

“That job highlights the trend to natural and clear finishes that let the timber shine rather than changing its appearance and colour,” says McLean. Though he adds that the Sikkens product is not 100% clear.

“There’s still a subtle pigment. We’re big believers that pigment is the first line of defence against the sun in Australian conditions, with the amount of UV we get. Anything on the market at the moment that is absolutely clear requires a lot more maintenance as it doesn’t have that durability. If we were to bring something fully clear to the market it would have to be well-tested in Australian conditions.”

Water-based quality

Sikkens has traditionally been known for its oil-based ranges, but the brand has recently moved into a high-end water-based range at very competitive pricing.

“We were one of the last to come on board with the water-based product,” McLean says, “because we had to make sure it was right.

“The expectation is that the oil-based system will last longer, but with our new BLX-Pro water-based system, it’s just as long-lasting if not longer in the exterior tests we’ve done on windows, decking and doors. It’s a one-stop shop product and has excellent durability, especially for coastal areas and pool surrounds. In salt-water areas, it’s highly recommended.”

McLean admits he wasn’t an immediate convert: “I was never really a water-based fan,” he says, “but while I was trialling it with painters, I started using it myself and it has impressed me. The price is on a par with the current options now, and you save considerably on labour.”

Testing done through Sikken’s R&D department has shown that BLX-Pro is one of the longest-lasting water-based finishes on the market, with excellent protection.

While still quite new, it has real traction in the market and McLean has seen some of his regular customers switch over to it from the oil-based options in the Cetol range for various reasons. One such customer is a painter who regularly works up in Port Douglas, Tropical North Queensland.

“He was working on a residence where the doors and balustrades had been left to weather and were a bit damaged and looking the worse for wear, but stripped them back, used the BLX-Pro, and he’s managed to bring them back beautifully,” says McLean.

A Port Douglas door that had been left to weather (left) then revived with Sikkens BLX-Pro.

“Because it’s so humid up there, and the weather can change from sunny one moment to very wet the next, quick drying was a factor. The BLX-Pro has a two-hour recoat, so he could get the job done in a day. With the old oil-based systems it’s 24-hours per coat, and you need three coats.

“For him it meant he could get in and out and get the job done while still achieving a premium finish with maximum protection. It was the first time he’d used our water-based and he was so impressed he sent me snaps from his phone. He also works on the resorts in the region and will be using the BLX-Pro there as well, as it suits both domestic and high-traffic areas.”

McLean emphasises that it’s up to the industry to reinforce the suitability and quality of timber windows and doors at all stages of the process. “It’s not enough to just have the fabricators and builders understanding,” he says. “It needs to be earlier than that, so the design professionals are able to talk homeowners through the options available to them and advocate for timber. In my own role, I’ve had to realise that my customers, the painters, already know about Sikkens’ systems, but they’re having products specified by designers and architects. So we’ve moved our focus and built relationships there, so when a project goes down the channel, the decision is already there to use the Sikkens product.

“We realised we needed to be a part of that discussion early on and show the designers what our system does. No one system suits every project, but there are areas where we just shine. The timber industry needs to be doing the same.”

For more details, visit www.allegion.com.au, www.humedoors.com.au, www.sikkens.com.au and www.weinig.com.au

Main Image: Hume’s Evolution Complete soft closing system from Hume, makes opening and closing doors a breeze – especially for older users and children.