After more than 20 years inspiring new timber builds and technologies, this year’s TOC event brings some exciting changes that will make it more accessible than ever.

Last year was decidedly not a good one for conferences. But as the Frame Australia team regretfully cancelled the 2020 Timber Offsite Construction [TOC] event, they took the opportunity to re-imagine it for the future. The result is a refreshed format that is more accessible than ever before and targets its various audiences more closely.

The 2021 TOC will run on 22 and 23 June, both live at Crown Promenade Melbourne and online. This year’s theme is ‘Timber & Technology: The Zero Carbon Future’ and will focus on current trends that are changing the way we build our homes and cities for a more sustainable world.

While Frame events have always showcased innovation and encouraged collaboration, recent events have seen the model refined to broaden its impact.

At my first TOC, I remember a question from the audience about how offsite construction methodologies could be made more relevant to the average fabricator. There was a bit of argy-bargy in the reply. Both sides had a point: many of the case studies that year were Tier 1 buildings that represented multi-million dollar investments, like Forte and 25 King. These were the work of high-end developers and builders and the large-scale fabricators who work closely with them. At the same time, not a lot of fabricators were working outside the traditional models of trusses and wall frames, so mid-rise builders moving into offsite work who did want to expand the pool of fabricators weren’t spoiled for choice.

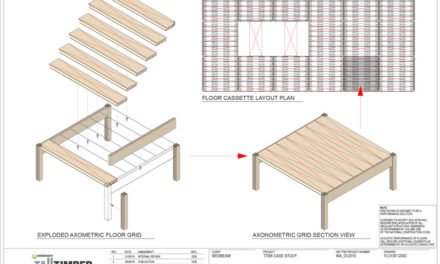

How quickly the sector has changed. Cassettes have boomed in most states, many more fabricators are manufacturing large floors and wall panels for quick on-site assembly, and there’s been a strong rise in designers and developers taking advantage of offsite construction to deliver faster, cheaper and safer builds for projects ranging from townhouses to daycare centres.

Credit for that change is rightly shared among EWP manufacturers and suppliers – who have done a lot of work in educating designers and fabricators about what their products can do and how to do it; fabricators who have expanded their offer and often invested in new machinery for it; designers who have changed their practice to reflect design for manufacture and assembly (DfMA) principles; and developers who have backed the others with their cash. And Frame’s TOC events deserve their share of credit, too.

An important part of recent TOCs has been designers talking about what succeeded and what they could have done better in their projects. Panels have become very hands-on, with real-world examples and surprisingly open accounts of various issues – including some very honest discussions of fixing mistakes (and saving others from repeating them). While some presentations are definitely still designed to inspire, many others are highly practical master classes.

Now, thanks to the 2021 format refresh, TOC is no longer restricted to in-person.

“The event is now ‘hybrid’,” says Kevin Ezard, Frame Australia founder and director. “So we’ll welcome delegates and speakers from around Australia and globally, providing access to both national and international contacts. The new digital programs will have interactive connections for exhibitors to network with delegates both attending and online – that’s a big update this year!”

Sessions will combine live streaming international presenters with in-person local speakers, to provide comprehensive and interactive global coverage of topics by world-renowned experts, without any lockdown or quarantine risks.

Registration fees have been reduced to make TOC more accessible, with Virtual ticket online session fees only $95 per session or $195 for the full two-day event. In-person attendees can also opt to attend specific sessions; a saving on the whole-event cost. Website registration will be live this month, with a range of booking options and opportunities for Partners and Sponsors to come on board also still available.

“Fabricators should definitely attend the Manufacturing and Technology session, which has some great speakers,” says Ezard. “Opening the session will be Gerry McCaughey the chief executive and chairman of Entekra USA, which is one of the largest home prefabricators in the world, plus Ola Skoglund, chief operating officer of Randek Robotics presenting on robotic digital processing and assembly for timber building construction.

“The building project panels will also be very relevant. They’re currently being finalised and that information will be released in the next month or so. They’ll cover a spectrum of innovative projects from mid-size to large buildings.”

The conference sessions are grouped into the following themes:

Building design influences

The built environment is a major contributor to climate change, accounting for around 40% of emissions and of 25% waste. This needs to change by working together towards a net zero and regenerative built environment in a socially responsible way. The construction industry should be part of the solution to deliver net zero projects and regenerative places.

Automation in mass wood building design from architectural concept to finishing with manufacturing level drawings is now a reality and makes whole-of-life design possible. Rethinking buildings as component systems in conjunction with new technology platforms can boost production of digitally fabricated products including CLT, glulam and other wood components for construction, help to speed delivery of the much-vaunted circular economy.

Construction productivity

High productivity can be achieved by improving speed to market; moving labour from the field to the factory; leveraging technology for every process; and providing a high quality, responsible product. These goals describe how to design and build with mass timber, combined with a platform approach for project delivery with significant improvements to productivity.

DfMA is a crucial part of process simplification and cost reduction that focuses on ease of manufacture and efficiency of assembly to minimise costs. Hybrid materials and construction systems are becoming prevalent as designers and manufacturers seek to maximise the benefits of materials by harnessing the potential of each component.

Manufacturing and technology

Residential construction in Australia has a high level of truss and frame prefabrication, but a relatively low level of panelisation compared with global trends. The growing trend is to reduce labour on site with more value adding in prefabrication to achieve faster construction, improved quality and higher turnover for both residential and commercial buildings.

Robots can now collaborate and perform numerous multi-functions including cutting, routing, milling, nailing, gluing, marking and component assembly of finished panels ready for site installation. Digital processing in automated production generates completed elements with the capability of each component to be totally unique.

Global wood building projects

The shift towards sustainable building materials is creating a massive global surge in timber and mass wood construction with a vast array of projects from mid-rise to high-rise buildings.

This session will include speakers on current building projects that have faced logistical and engineering challenges that have been overcome with new and innovative cost-effective design solutions that will change the way we build in timber and mass wood in the future.

Highlights include speaker presentations on the largest mass wood building in the world now under construction, and the tallest hybrid mass wood building in the world currently in design phase.

Building project panel sessions

Selected building construction projects with unique features and/or innovative design concepts will be discussed by key influencers in the projects. Panels are comprised of developers, architects, engineers, builders and timber suppliers discussing ‘real life’ project challenges encountered and the solutions developed to achieve the design and construction outcomes required.

Projects selected will provide a range of timber and mass wood construction systems including mid-rise residential, unique hotel accommodation, office buildings, high rise apartments, university campus facilities, community welfare facilities, commercial precinct developments and more.

Panels will be followed by Q&A sessions and open discussion with delegates.

Timber Offsite Construction 2021 runs Tuesday and Wednesday 22–23 June at Crown Promenade Melbourne and online. For more info and to register, visit www.timberoffsiteconstruction.com

Image: Complexe Synergia in Quebec has had great response to its exposed mass timber design from the tenants, leading to a more contented workplace. Image courtesy Frame Australia.