EWP are timber, just like pine, which means treatment can help deliver better outcomes and longer lifespans for these manufactured products as easily as for light framing timbers.

Stuff. If it’s made right, stored, handled and maintained correctly, it will last forever. It is important with any material that you treat it right. For timber to last forever, like in the Horyuji Temple in Japan (circa 700AD, making it over 1300 years old!) it essentially needs to be protected from moisture and critters. The basics are as simple as that although there are a few factors to consider here.

Timber has a natural durability which relates to the species. if used in harsher environments this can be enhanced through preservative treatment. Engineered Wood Products (EWP) are no different as they are made from timber, but there are some specific considerations when you re-manufacture solid timber into any EWP. EWP in this article will focus on LVL, plywood, glulam and OSB, as well as particleboard (although there is some debate on whether this is an EWP or not). We will go through some of the different hazard classes and note how EWP are treated and what precautions to take.

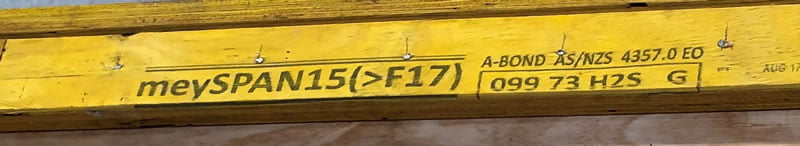

H2S is normally the lowest level of treatment for EWP. This provides protection against termites and borers for locations south of the Tropic of Capricorn, similar to H2F (or blue pine). With the EWP described above, H2S is mostly associated with a glueline treatment in LVL. This is where the chemical is added into the adhesive during manufacture, meaning every glueline in the product is infused with termiticide. The benefit of this is that the LVL is treated throughout the entire cross section, so any cuts, notches, drilling or planing do not have to be re-treated. There are also some EWP that are envelope treated (LVL and glulam), which is acceptable in accordance with the treatment standard. Very few structural LVL products are supplied in Australia today that are untreated. Distributors and manufacturers have chosen to stock H2S due to the small cost difference and also to reduce the amount of stock lines held.

H2 treatment is also used for termites and borers, but with an increased level of chemical it can be used Australia wide and specifically to account for Mastotermes darwiniensis which is prevalent in northern regions of the country. LVL is usually treated to H2 level through a post manufacture LOSP/vacuum pressure vessel treatment from H2S feedstock. The small volume of H2 product that is required makes this a better economic proposition. Panel products, including plywood, particleboard and OSB are normally supplied as H2 through glueline treatment. Again, the reason is to allow a single product to be made and sold country wide. When we come to glulam, this is where there starts to be a difference. Glulam is made from lamella which are laminated one on top of the other. To achieve H2, these lamella are treated to H2 prior to manufacture, meaning the final beam is treated throughout.

Both the H2 variants discussed above are intended for internal use, protected from exposure to the weather. The next hazard class is H3, which is an external above ground application, and the standards define it as “subject to moderate periodic wetting and leaching”. In addition to termites and borers, this level of treatment also needs to deal with decay due to moisture. I am not aware of any H3 chemical that can be added into adhesive, although companies are working on this so expect it to be available in the future. Due to this, there is no commercially available H3 OSB or particleboard. LVL can be treated to H3 in a pressure vessel. Doing this is not recommended (but can be done) as the vacuum impregnation of chemicals into LVL puts large stresses on the gluelines and can cause long-term issues. This is where H3 glulam has good advantages. The individual lamella is treated (as with H2) so once made there is not the stresses on the adhesive as with LVL. Plywood is treated to H3 in a pressure vessel and this does not have as large an effect as it is usually quite thin with less dimensional variation during the vacuum process, being a panel product.

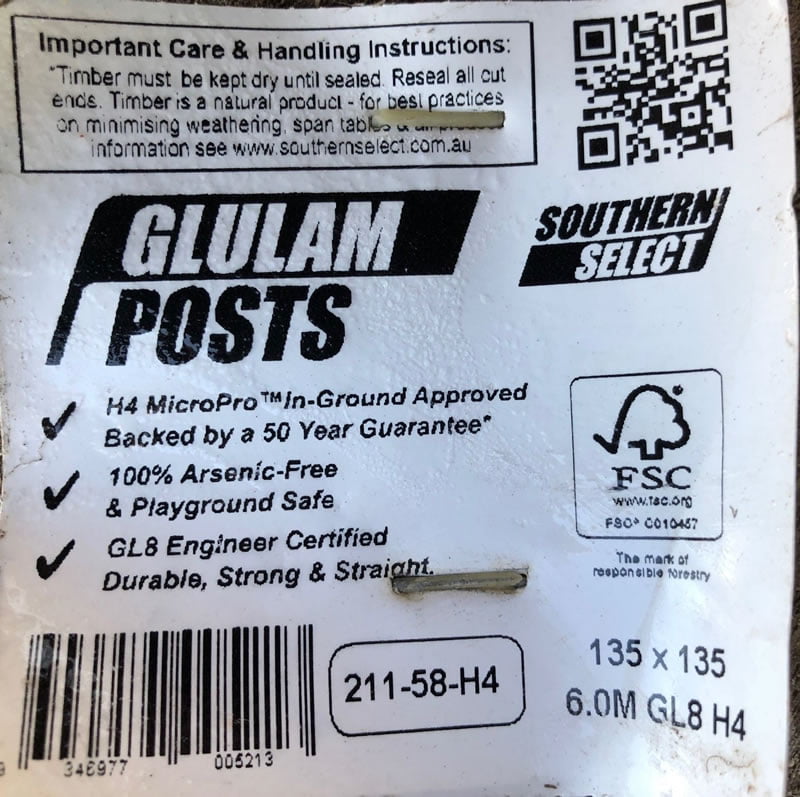

The next hazard class is H4, designed for severe decay and intended to be used in-ground. The only common type of EWP used in this instance is glulam, which is utilised as post sections. Then we have H5 and H6 which are not generally applied to EWP.

Checking compliance

As with all products you should make sure any treated product is compliant. Each piece is required to be branded in accordance with the AS 1604 series of standards and also must have a treatment plant number (see images below). The treatment plant numbers are all searchable on the TPAA website at www.tpaa.com.au.

In construction, items to note are similar to solid timber. These include re-treating any cuts or notches on H3 EWP. There are both spray cans and paint-on chemicals to be used here, and this will impact on any possible warranty claims if not undertaken. Then the general aspect of detailing for durability is extremely important, especially for EWP. Protect end grain (capping, tapered end cuts, etc), prevent water pooling (covering tops of members and restricting horizontal surfaces) and pay special attention around connections to allow water drainage and good ventilation.

There are many resources relating to durability of both general timber and also specific to EWP. The WoodSolutions Technical Design Guide #5 is quite comprehensive, and there are industry publications such as the Meyer Timber guide to Durability of EWP. You can treat stuff well, but the only way to make sure that EWP perform in the long term is to epitomise the Roy Head song (with an awesome cover version by George Thorogood) and ‘Treat Her Right’.

For more information on this topic, contact George Dolezal via email at GeorgeD@meyertimber.com.au

Image: Horyu-Ji Temple, Shutterstock/Vladimir Zhoga