Metsä’s new tall timber option lowers construction carbon.

While the world would doubtless be a more beautiful place if all construction were timber, here in reality we’re trying to make it a more sustainable place by increasing the percentage of timber in builds traditionally dominated by concrete and steel.

Finnish forestry group Metsä has been tackling this problem from multiple angles for some years now, and its latest contribution is one of the easiest to increase the volumes of timber used.

Metsä Wood’s hybrid sandwich wall element takes a traditional concrete sandwich wall and replaces the internal load-bearing core panel with a Kerto LVL Q-panel. The structure of the element remains otherwise the same; the façade is made from concrete with an insulation layer. “As a material, Kerto LVL is very comparable with concrete” says Ari Mättö, Structural Designer of JM-Rakenne Oy, one of the companies that collaborated with Metsä on the project. “The compressive strength of the Kerto LVL panel is as high as that of C25 concrete. The tensile strength of the panel is at the same level, whereas in concrete it is 10% of the compressive strength without steel reinforcement. In a hybrid sandwich element, the reinforcement is needed only in the façade.”

With similar connections and lifting loops to those used in concrete elements, it’s a straightforward swap for the builders.

“Metsä Wood currently works with European and Australian companies to produce similar ideas that fit the local way of construction” says Jussi Björman, director at Metsä Wood. “Half a dozen designs are being prepared for publication this year.”

These designs and the hybrid sandwich wall element design are already available at Metsä’s Open Source Wood platform and the hybrid sandwich wall elements are being used at Metsä Fibre’s new Rauma sawmill.

For more, visit www.metsawood.com

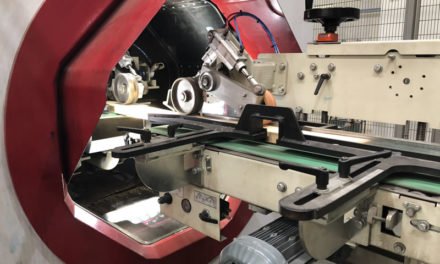

Image: The inclusion of timber lightens the panel while retaining quality.