EWP specialists Metsä Wood add their recent Port of Amsterdam build to their online resource kit.

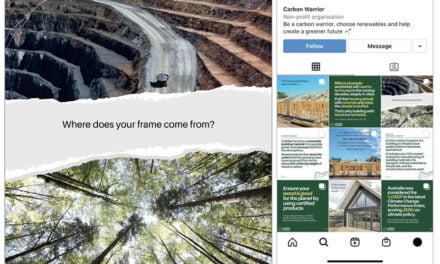

Supply of LVL into Australia out of Europe is still limited from many major brands including Metsä Wood. While the company’s recent announcement of a new 250-million-euro plant due to come online in early 2024 is welcome, Metsä isn’t resting in the interim. Instead, it has recently added to its resources library with new information and tools that will be valuable to Metsä customers and also non-customers seeking to show the benefits of EWP and panelised construction to clients.

The Carbon Storage Calculator is a handy tool for Metsä customers. Simply choose your engineered wood product, enter the cubic-metre quantity of it in your project (your order size) and the calculator will deliver the quantity of carbon stored in that product for the full life cycle of the building. It’s an easy but effective way to back up the claims of a sustainable build.

For anyone wanting to be inspired by – or help your clients understand the potential of – LVL and prefabrication, Metsä’s Offsite Construction section includes a library of reference builds. The Nautical Coordination Centre at the Port of Amsterdam is the most recent addition to this resource.

Designed by WRK Architects, the major material used in the structure is Metsä Wood’s engineered Kerto LVL. Fitting in with the Port of Amsterdam’s strong focus on the circular economy, all the floor, wall and roof elements were prefabricated by the Belgian timber element manufacturer Dupac and delivered to the building site ready for assembly. The Lego-like assembly is more than just a fast building method: panels can be later removed and re-used in another build. The minimal requirement for fixings further lowers the carbon cost of construction.

Subtle differences in the panels meet different usage requirements: floors are designed to minimise vibrations, insulation is added to the walls and roof and extra ribs are used to strengthen the panels beneath sliding doors. Thicker LVL helps to meet fire safety requirements

“This beautiful and natural building material contributes to a pleasant working environment and fits the Port of Amsterdam’s ambition to build sustainably,” says Benjamin Robichon of WRK Architects.

“Those who step in the building are really surprised. A practical open-space working environment greets you when you enter the building, which is ideal for a 24/7 company like the Port of Amsterdam. The industrial appearance of Kerto LVL products is fully visible, and the large floor-to-ceiling windows offer a view of the IJ river.”

Solar panels and a heat pump are the finishing touches for this energy self-sufficient building, which stores a CO2 equivalent of 159T.

Find links to the Carbon Calculator and Port of Amsterdam build at www.metsagroup.com/metsawood/