The branding on quality LVL can tell you everything you need to know, as can its absence.

By Craig Kay, national product engineer, Tilling

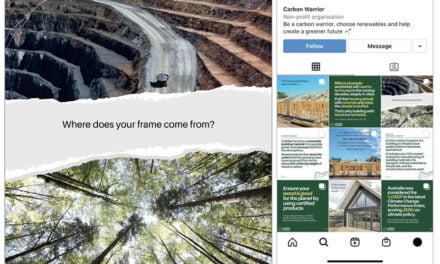

A graphic illustration conveys a stronger message than words. The phrase “one picture is worth a thousand words” was invented by an advertising executive, Fred R. Barnard. To promote his agency’s advertisements, he took out an advertisement in Printer’s Ink in 1921 with the headline “One Look Is Worth a Thousand Words” and attributed it to an ancient Japanese philosopher. Six years later he changed it to “Chinese Proverb: One Picture Is Worth Ten Thousand Words”, illustrated with some Chinese characters. The attribution in both was invented; Barnard simply believed an Asian origin would give it more credibility. Never let truth get in the way of a good story and a bit of a lesson about advertising.

Whatever variant of the phrase is adopted, the wisdom in the message is still equally valid. While the mandatory marking on LVL in conformance to the AS/NZS 4357 LVL standard is not a ‘picture’ per se, the few words and numbers selectively placed are communicating to the trained observer a far bigger story.

Below is a typical marking on some LVL marketed in Australia. Many manufacturers may add some further marketing type data such as a reference to the product being equivalent to a common F grade of timber or highlighting a proprietary short term water repellency coating or similar.

DECODING THE MARKS

We can read the story being told here by expanding the individual elements.

Where compliance to AS/NZS 4357 is claimed, the branding of the LVL must be in conformance to clause 1.8 of that standard.

The manufacturer’s name or registered mark: The registered brand or marking that, in conjunction with published literature, clearly identifies the structural properties that apply to that product. This information is vital so that anyone using the product knows where to get further information.

Grade: There is currently no codified standard for LVL grades, so it is vital that there is corresponding published literature that gives users the necessary characteristic design strength and stiffness to use in any design calculations. It is unfortunately common to see LVL product with just a numeric descriptor, but in the absence of supporting data, this number is at best meaningless and at worst possibly deceptive.

Marketing: Logos for other certifications/accreditations the product may meet.

Reference to the standard: The referencing of the standard is a mandatory requirement if compliance is claimed. It is mandatory that manufacturers making a statement of compliance with this Australian/New Zealand Standard on a product, packaging, or promotional material related to that product are required to ensure that such compliance is capable of being verified.

Bond type: Bond types for LVL are defined within AS/NZS 2751.1 Adhesives for timber and timber products Part 1: Adhesives for manufacture of plywood and laminate veneer lumber (LVL). Notwithstanding the reference to AS/NZS 2751.1 which lists different glue types, clause 2.5 of AS/NZS 4357 prescribes only a phenolic type of resin from that standard.

Formaldehyde emission class: AS/NZS 4357.4 specifies three (3) formaldehyde emission classes, E0, E1 and E2 along with the test methods to allow determination of the corresponding value.

Limitations of end use: This is a marking requirement of the LVL standard, and in this case indicates that the H2S preservative treatment applied during the production process is suitable for use south of the tropic of Capricorn only, and that additional treatment needs to be applied if the hazard level rises to H2.

Preservative treatment: If preservative treated, the marking must conform to the AS/NZS 1604 standard series. The series of numbers and letters (in this case enclosed in a rectangle) all convey important data about the type of preservation and the hazard class it is deemed suitable for.

Unique Identifier for the treatment plant: The first three-digit number is a treatment plant number, this number is allocated by the Timber Preservers Association of Australia (TPAA) who maintain a database of treatment plant numbers that can be accessed on their website at www.tpaa.com.au/treatment-plants/. Visitors to this site can search to find who has completed the preservative treatment

Unique identifier of the preservative (chemical No): The second two-digit number in the rectangular box in the illustration is a preservative number referenced in Appendix E of AS/NZS 1604.1-2021. Only those chemicals listed in Table 3.3(C) and 3.3(D) conform to the above standard for H2 hazard classes.

Hazard class: Hazard classes shall be used as the basis for specifying the preservative treatment of the LVL. The H2S hazard class in the above example is defined in Table 1.5.2 of AS/NZS 1604.1-2021.

Penetration Pattern: LVL shall be additionally marked with the penetration pattern code in conformance with Table 1.5.3.3.5. in the above marking example, the “G” outside the rectangle indicates that the H2S treatment has been achieved by a glueline additive of the active chemical. For LVL with a cross section ≤18,000 mm2, conformance to the standard may be met with a 5mm envelope treatment, in this case the penetration code would be “E”.

In a perfect world every stick of LVL offered for sale in the Australian market would be manufactured in accordance with the applicable standards and therefore be appropriately marked.

To produce LVL that is:

- in every aspect conforming to

AS/NZS 4357; - accompanied by comprehensive design guides, engineer certified span tables and free design and take off software tools;

- accompanied by a distributor offering sophisticated technical support functions along free take off services;

requires a significant level investment, not just in manufacturing but also in product support.

Unfortunately, in this period of short supply of LVL, the market is witnessing an influx of new, inexperienced operators, who in many cases demonstrate that they have limited or no understanding of what does or does not meet the relevant standards.

The first hint of this lack of knowledge is often identified in the marking of the product being offered. As described above, each component of the marking tells the experienced user a great deal of information about the product, but in a shorthand or coded fashion. The lack of some important information can cause the product to be inappropriately used which in the worst-case scenario, could present a safety risk.

The markings on LVL are there for a valid purpose, and although brief, actually do tell a larger, important story.

Craig Kay is the national product engineer for Tilling. For more information on this topic, contact Craig Kay and the Tilling engineers via email at techsupport@tilling.com.au