As the recession starts to bite and Covid plays havoc with both freight and currency stability, a campaign to Buy Australian Timber First hopes to save local jobs throughout the sector.

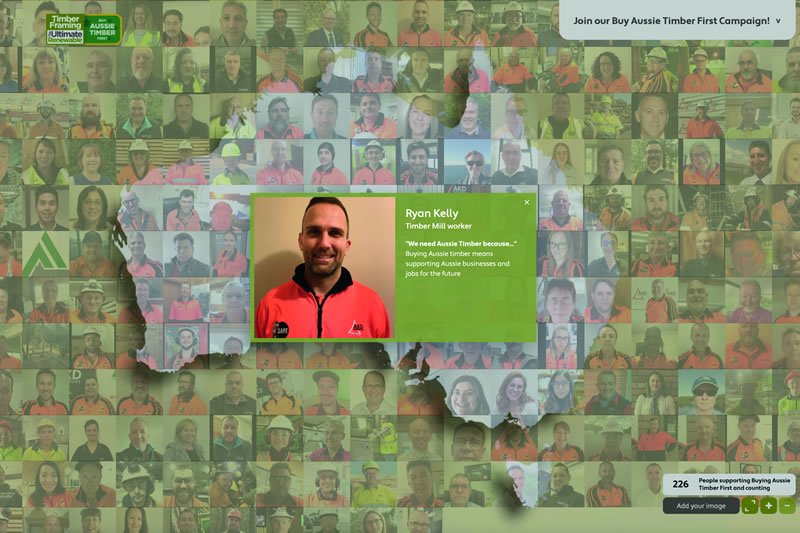

High-vis is the dominant fashion trend in the sea of faces looking out from the web page. Over 200 members of the Australian timber industry so far have signed on to the Buy Aussie Timber First campaign, launched in June by AFPA and six of Australia’s biggest suppliers. Each signatory comes with a name, an industry job and a reason for why they are giving their support.

It’s a timely action. With uncertainty around international freight timing and costs and an Australian dollar that’s moved US12c (both down and partly back up) in the past six months (with the drops starting well before Covid-19 hit internationally), simple logistics suggest that a focus on local supply where possible is a practical position.

While no one is pretending the industry doesn’t also need importers, the call is for merchants, fabricators and builders to look at their suppliers and, other things being equal, favour the local product in a bid to hold onto Australian jobs and manufacture.

The first six signatories were the CEOs and MDs of some of the biggest suppliers in the business: Shane Vicary from AKD, Stephen Dadd from Boral; Jon Kleinschmidt from Hyne Timber, Linda Sewell from One Forty One, Ian Tyson from Timberlink and Patrick Warrand from Wespine. They’ve been joined by a range of voices from industry associations and groups to business owners and workers, all conscious that when it comes to keeping Australian timber and construction jobs going, it’s up to all of us.

We spoke with some of the people supporting the campaign, why they are happy to throw their weight behind it and what they hope to achieve.

Industry backing

David Little, CEO of TABMA, isn’t mincing words. “In other fields, we’ve lost entire manufacturing industries to overseas because we couldn’t compete, we weren’t cost effective,” he says.

“But in the timber industry, Australian manufacture is just as good as anywhere else. In fact, we’re sometimes world-leading, and it’s just as cost-effective. We’ve got world-class mills here. I’ve just been talking with Hyne – they’re producing world-class products and we must support that.”

Little has been getting the word out to his merchant members in a bid to spread it further through the builders they supply to. “For the general builder, it’s in their DNA to buy locally and buy Australian,” says Little. “That’s why Bunnings has had such a hard time getting into the trade sector, because it’s not in the nature of your classic Aussie builder to trade with a big corporation.”

Brett Martin, trade operations manager – Independent Hardware Group (IHG), agrees: “Aussie-sourced timber is generally what our network of trade stores prefer, as do their customers. Generally, builders know the product, know the best way to use it and understand its capabilities, more so than imported products. They know the strong brands of Australian timber companies and seek out that ‘local’ content, knowing it’s responsibly sourced and produced.”

IHG is Australia’s largest timber wholesaler to the independent trade outlet market. Martin, who has decades of experience in the industry and works closely with Mitre 10 and other IHG store owners around the country, adds, “While there’s definitely a balancing act for us between local and international supply, our members absolutely focus on securing Australian production as our primary source to supply the housing and construction market.”

Geoff Harris, IHG’s general manager merchandise has spent many years working in both local and international timber supply. “The Australian timber industry is critical to the viability of the total building industry supply chain,” Harris says.

“For us, locally supplied product provides added benefits for our members such as shorter lead times, cost stability and fit-for purpose use with in-market product technical support. We and our members have really close connections to local suppliers and we’re seeing mutually beneficial outcomes for both stores and suppliers as we work together to ensure we meet our builders’ current and future demand for timber products.”

Harris points out that the jobs arising from increased local supply stretch well beyond the timber industry into all parts of construction, hardware supply and general service requirements. “A lot of that employment is based across regional Australia, which is very important,” he says

Little has found that one of the few upsides to come out of the pandemic and its associated problems has been an increased support for Australian manufacturing. “There’s a real hunger and energy out there in the country at the moment to buy Australian,” he says. “I think this campaign will resonate with everyone. And the thing I personally like the most is to see the CEOs of all these organisations working collaboratively for the benefit of the whole industry. Timber has previously struggled against the highly organised steel sector, so lots of us looked at that and felt uplifted.”

Fabricator friendly

Based in St Marys, Western Sydney, MCM Frame & Truss has been delivering high-quality products across the Greater Sydney region for 25 years. Owner Mark Hull has long been a keen advocate for the industry and first heard about this campaign from FTMA’s Kersten Gentle.

“We’ve been a supporter of Australian-grown for many years,” Hull says. “So I said to Kersten, ‘We won’t be changing’ and she looked at me in surprise, but I told her, ‘We’re already there. That’s what we do!’”

MCM uses a wide range of light timber and engineered products in its range, which encompasses floor panels and cassettes as well as standard frames and trusses.

“Our philosophy has always been to buy home grown,” Hull says. “It’s not patriotism, it’s because overall the product is made for our conditions, so it performs better. And then on top of that we have the added benefits of easy, reliable supply and supporting jobs and the community.”

Hull compares the zero issues he’s had with his supply throughout Covid with those of his colleagues. One engineered timber supplier he knows has had an imported delivery pushed out from June to August.

“We buy a lot of our engineered product in from Hyne and Wesbeam, who both manufacture in Australia, and their engineered product has been super reliable with no issues,” says Hull. “In fact, if we’re going to compare them to the imported product, you’d have to say they’re better.

“That goes beyond just the product itself. We get support from these businesses in terms of stats on sales in quotes and directions, as well as great service. Wesbeam in particular keep coming up with new products and new ways of using them.“

This understanding of the local market’s needs is an additional benefit of using local supply that Hull appreciates, though he’s a pragmatist. “I can’t say we haven’t used imports over the years, we have from time to time, especially when the industry is in a massive growth phase and the local supply just can’t keep up with demand. We need to keep the builds going.

“The fact is right now, we don’t need a lot of imports, and that’s why this campaign is a good thing. Down the track, there’ll be another boom and that will change. It’s a bit of a double-edged sword for the importers – we only want them when we need them – but they make good money when we’ve got a lot of building on here.”

For all that Hull will happily talk about the wider benefits of timber at length, his real focus, rightly, is on his business and staff. “I’m all about doing the things that deliver a great end product, because that means I get more jobs,” Hull says. “Not only does local supply help me do that, it helps me do it easily. I sometimes go to other suppliers to get a pack here or there and they have real issues with the dollar fluctuating. It would be a nightmare if I had to sit down every month when planning our monthly stock and volume and add worries about what’s going on with the dollar and all the ships and arrival times: I don’t have to deal with any of that.”

Steadfast supply

The team at Footers Structural Timber have also built the majority of their business around local supply. The third-generation family business in SA sells roof and floor trusses, as well as timber for the local building market. “We’re 99.9 per cent residential construction, so most of our work is at that end of the market,” says Nick White, general manager of operations.

“Buying Australian is our default. Some of that is a sense of whatever country you’re in, you’ve got to support the work and jobs in that country, but there are also practical reasons backing that up.”

The software for Footers’ trusses is set up for Australian product, which suits the at times dramatic SA climate. The majority of structural timbers for their truss plant are bought in from OneFortyOne, TimberLink and AKD – some via a wholesaler.

“OneFortyOne is physically quite close to us,” says White. “Most of their timbers come through Mt Gambier and that’s not just Australian-made, it’s South Australian-made! If you’re going to support your country, you might as well support your state.

“And of course, the closer the mill is, the better for everybody because of the freight component. Timberlink has a mill there, too. So it’s lower freight costs and carbon costs, and you don’t need to worry about border closures. That said, so far, we’ve found freight during Covid has been very smooth. Even goods coming out of Victoria and NSW have been fine, though time will tell whether stronger restrictions change that.”

Footers also buys in LVL from Wesbeam for their truss line, and, for the timber sales side of the business, glulam from Vicbeam and Warrnambool Timber Industries, “and some Hyne beams through Wesbeam,” White adds.

“The quality of the product is right up there, but what makes the biggest difference is the depth of their understanding of the local market. I had an enquiry from a builder recently about the use of LVL in bushfire zones. They’re doing a rebuild job after the fires. I emailed the supplier here and they got back to me straight away with all the information, which I could send directly on to my builder. That was brilliant.”

The product range on the timber sales side includes some imported product to meet the desires of local builders. Even there, Footers has looked for a relationship that has benefits for the wider Australian market. “We buy imported product from Stora Enzo: they’ve proved to us that they’re here to stay and are interested in this market long term,” says White.

White contrasts this with international companies that have come into the Australian market when the AUD and demand are high and then pulled out at the first hint of an economic downturn.

He says, “We like to build a strong relationship with our suppliers so that when things get busy, we can count on that to guarantee supply and then when things are quiet, we can often get better deals. We want to be a customer of choice for our suppliers in the same way we’re a supplier of choice to our builders.

“Does that work for us all the time? It’s hard to tell. You don’t know what supply you haven’t got. We do know there have been times of limited fibre supply in recent years. We’ve seen fabricators who’ve had to reduce their working hours because of supply issues, but we’ve never had that issue. Maybe that says we’re doing the right thing and our suppliers want to deal with us when demand gets hard because there’s a long relationship there where we’ve done the right thing by each other.”

Brett Martin adds that even for fabricators operating on a smaller scale, the benefits of local supply show quickly. “Through our IHG network, we hold a strong footprint in the local F&T market with over 30 plant operations linked to the IHG network. Their primary source of supply is Australian production, and using their collective volumes, we have the ability to secure the appropriate stock demand at a competitive rate to keep costs manageable within their business. The close relationships at plant level ensure the level of quality and service is maintained.”

Growing markets

White learned about the campaign through LinkedIn and was impressed to see the leadership behind it, particularly the unity presented by the Big 6 firms.

“I can’t say I’ve seen a campaign like this before,” White says. “It’s been a traditional thing in our industry that we’ve been very individualistic rather than looking at the bigger picture of the sector as a whole.

“It’s a very healthy sign for the industry in general that we can come together on a project like this. I think it’s been a long time coming and I hope it’s not the last time it happens. One of our biggest enemies in domestic housing is steel and they’ve got major companies like BHP with very deep pockets who can fund the steel case for everyone. That’s given them the upper hand on the marketing side for a while. Hopefully, this is a sign that we can present ourselves as a united industry and grow our share of the market across Australia, both through this crisis and long after.”

He points out that fabricators, suppliers, hardware stores and even specifiers are the natural targets for the campaign. “Timber is a critical structural product for building houses in this country, but the vast majority of what we sell gets covered up by the builder and the end user,” says White.

“They’re not focused a lot on where the timber comes from, they just want to know it’s of a quality and a grade that is suitable to meet the requirements of the project and then they move on. It’s up to us to educate them about what Australian product means in terms of both the product benefits and the flow-on benefits to the wider economy. All the ads tell us that we’re all in this together. The way we can help those who are struggling at the moment is to keep as many jobs as we can in Australia so that people have money coming in to aid and speed up the recovery.”

White is focused on getting through the crisis, but he’s very realistic about where things are currently sitting. There’s been a downturn in workload and the Footers’ team is juggling responsibilities as never before.

“I think that by and large we’ve been very successful at keeping staff,” he says. “We’ve made a conscious effort to reduce people’s hours throughout the firm where needed rather than just lose people, because the world’s going to come back and need housing again, and if we’ve got to completely retrain a workforce because we lost everybody, we’re going to be very slow to bounce back.

“Our loss of staff has been very minimal so far. Certainly people want more hours! But hopefully, with government incentives and the jobs we have coming down the pipeline, we’ll be well placed to bounce back quickly from all this.”

For more details or to add your support to the campaign, visit www.buyaussietimberfirst.com.au, or visit www.tabma.com.au, www.mcmframes.com.au, and www.footers.com.au