Trusses and air conditioners often don’t play nicely, but this design might fix that.

As a lover of all things building industry and the English language, I often have a chuckle about some of the terms we use in building. My all-time favourite word is podger, which for the uninitiated is a steel-erector’s spanner with a pointy end that is used to align the holes.

There are thousands of other odd building terms like stylobate, finial and quirk. We in the truss and frame industry contribute by calling trusses weird names such as Funk, Warren, Howe and Creeper.

You could also pretty much build a person out of the housing body part names: a hip, knee, footing, weep hole, and a bottom (plate). And you could dress it up in skirting.

There’s another body part building term which keeps getting me into trouble; people look at me like I’ve just dropped my pants when I use it on site and in meetings.

The term ‘bosom’ describes the space between the top and bottom flanges of an I-beam or channel and the web; there’s a definite similarity in form between the building bosom and the human one. The term came to me via my first engineering boss, who was near retirement when I was a baby engineer in the late ’80s. It turns out that either it was an old and almost defunct term, or he was trolling me. A Google search comes up blank – well at least for this definition. Feel free to use the term – it’s useful to describe space that isn’t otherwise defined. But, be warned, you might get some odd looks.

So, I have a truss configuration invention and I am reserving the right to give it its quirky building term name.

As you know, the bane of our trusses are the following trades that cut, notch or otherwise mess with our roof trusses. Perhaps the worst offenders are air conditioning installers who will cut out a web or two to fit in a junction box or fan unit.

I vividly remember my second boss being ashen faced when the air conditioning installers had done their bastardry and the roof over a bowling club had sagged 100mm. He had to tell the establishment’s management that the building needed to be evacuated. Now!

A solution used in roof trusses is to miss out a diagonal, typically under a horizontal top chord, to allow the passage of air conditioning services. This isn’t great because this configuration truss is vulnerable to asymmetric loads such as live load on one roof face or wind loads coming from one direction. Some software might seem to design it but will not be looking at asymmetric loads – which may actually be the critical case for this truss type. If you do have this sort of gap in the webbing and the design is correct, then the bottom chord or a horizontal top chord should generally be heavier than a truss for which that web was actually supplied and designed. And, because a camber won’t stay in the truss, the overall design may need to be heavier anyway to limit deflections.

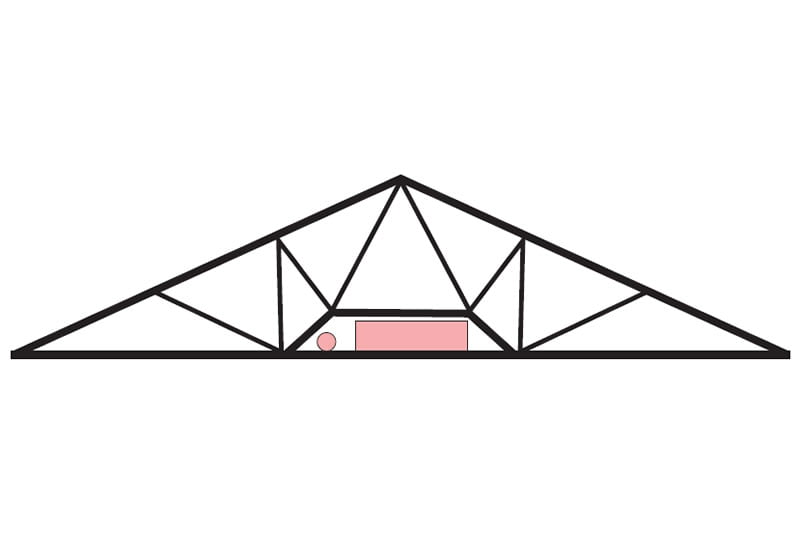

So, my truss shape invention shown in the diagram above solves that problem by giving a good clear space for the services to pass through whilst maintaining continuity of the webs from one side of the truss to the other.

At this point, the software writers for the nail plate companies are having a heart attack at the programming required to design this. But you could design it reasonably simply as a cathedral truss and manually detailing the bottom chord to go right through. You are not weakening the truss by adding that extra timber.

The lower bottom chord would need checking to carry service loads and the ceiling. You could size that from span tables as a ceiling joist. The nail plate at the joint may also need an adjustment. And in construction, the upper-bottom-chord needs to be restrained by binders and bracing at whatever the design restraint was for the bottom chord.

You would need a table press to make this thing and so, as an alternative, you could design the cathedral truss and supply the extra bottom chord as a loose member. And, of course, you need to charge your customer for the privilege of designing and building something that serves their needs in this way.

So, the moment you have been waiting for – the naming ceremony. I have picked a slightly comedic name in a nod to an episode of The Goodies which was my favourite childhood comedy show and, vaguely, to its appearance. I hereby name this truss configuration: the “Fishface”.

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News. Phone: 02 4576 1555, Email: pauldavis@timbertradernews.com