A spot of preparation can deliver a vastly superior result in both sports and timber. By Afzal Laphir, Principal Engineer, Meyer Timber.

Sporting stars know better than anyone how to achieve peak performance. They determine when an event is happening and prime themselves with the correct training in the lead-up to ensure they perform to their full potential. And timber is no different.

Timber products used in external applications are required to be durable for a long period. Some species are naturally durable, but most timbers need to be preservative treated to protect against decay and insects. This treatment alone is not sufficient to prevent the timber from weathering over time when exposed to the elements, which can lead to appearance concerns and eventually impact on performance and its design function.

The weathering process can be controlled by the application and regular maintenance of the various coatings that are commercially available. In addition to protection from weathering, proper finishing can also shield from UV light and protect from rapid moisture content changes.

Pre-primed (or factory-primed) dressed LOSP treated timber products are one of the most convenient options available in the market for outdoor applications. The range comprises structural products like beams, rafters and posts (see Image 1, below) to weatherboard cladding and fascia to finishing trims and mouldings (and more). These timbers are generally made from softwood species like radiata pine which is preservative treated and manufactured into the final section sizes using finger joints and/or glue-laminated technologies. The pre-primer only serves to temporarily protect the timber from weather and contamination during transport, site storage and construction. It is not intended for long-term exposure to the elements and therefore to achieve prime performance in outdoor use, the pre-primed timber must be ‘finished’ as soon as possible. Failure to do this can result in timber checking along the glue lines, separation of finger joints and possibly even require replacement for structural elements that are affected.

Before we look at the finishing of outdoor timbers it is just as important, or maybe even more important to focus on how they are detailed and constructed. Outdoor timber must be designed and detailed to minimise moisture entrapment, and this is critical around connections where there is timber-to-timber contact or close to other materials. Good detailing includes leaving gaps where possible to improve air circulation, using flashings to the top of timbers, bevelling ends to reduce end-grain exposure and protecting the end grain of timber by using cappings or end trimmers. Appendix B of AS 1684.2 provides some advice on this, as do the publications noted later in this article.

Finishing

Once pre-primed LOSP treated timber is installed it must be finished with coats of paint for added protection. Sometimes, it is preferable to apply one coat before installation to provide additional protection during the construction phase and also allow clear access to surfaces that could become inaccessible post-installation. Re-application will be required at regular intervals to preserve the surface appearance of the timber. The type of finish and the method of application should be in accordance with the coating manufacturer’s recommendations – they have done extensive testing of their products on various substrates and know how to maximise the life of the product.

When finishing pre-primed LOSP treated timber, the following measures should be followed as a minimum:

- As the primer only forms part of the final painting system, do not leave exposed to the weather for an extended period (four weeks or more). Otherwise, the surface may become chalky, requiring sanding and re-priming.

- Before coats of paint are applied, ensure the primed timber is reasonably dry (MC < 15%) and free from any dirt, oil or grease or other surface contaminants.

- Any notches, cuts or rebates made during installation must be re-coated with an approved preservative sealer. Similarly, any damages or imperfections should be scraped clean, primed and made good with putties that are compatible with the selected finishing.

- When using a water-based acrylic topcoat, apply two coats of a premium brand as per the manufacturer’s specifications.

- When using an oil-based topcoat, for optimum performance, apply an undercoat followed by two coats of a premium brand as per the manufacturer’s specifications.

- Pale-coloured paints give the best outcome as they absorb less heat and reduce the potential for degradation due to moisture loss.

- The off-cuts from pre-primed products should not be burnt. As with all treated timber, they must be disposed of by methods approved by local authorities.

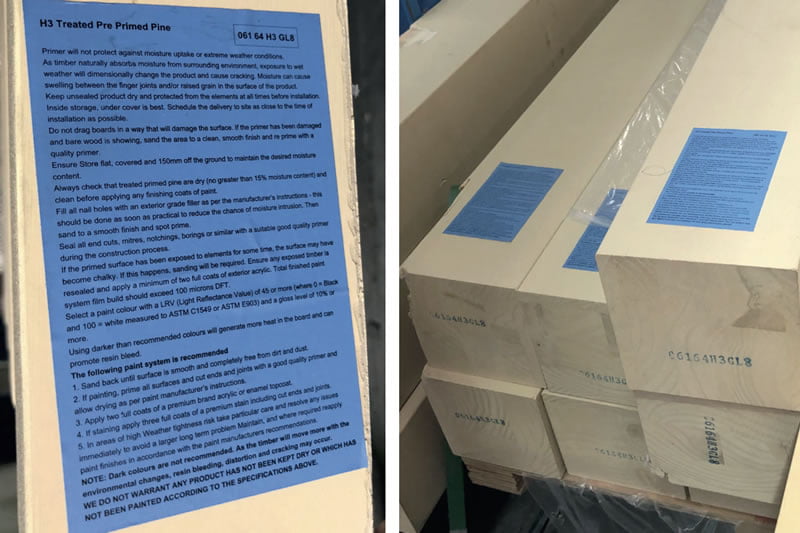

Most pre-primed products are supplied with a label (see image above) containing similar information as above. For further advice on this subject, contact your pre-primed timber supplier or refer to the excellent industry publications, namely Finishes for Exterior Timber (Mar 2014) from Timber Queensland, and Finishing Timber Externally (Sept 2015) and Timber Service Life Design Guide (Sept 2020) from WoodSolutions.

It is important to re-emphasise the need to protect the timber from weathering, which requires pre-primed timber to be augmented with additional treatment and regular maintenance. We must ensure the timber is primed for performance in an external environment, otherwise, it will be past its prime before you know it! The consequence of this may not be disastrous for a sporting star, but for timber, it certainly can be.

For more information on this topic, contact Afzal Laphir via email at AfzalL@meyertimber.com.au

Image: An example of a typical label included with pre-primed timber posts.