For practically every type of timber product you make, pre-oiling can help keep it looking and performing at its best from day one.

Pre-oiling is far from the sexiest topic, but like fibre and sunscreen, it’s worth every bit of effort in most cases. For a small additional cost, you add considerable value not just to your timber product, but to everyone down the line in your sales chain.

We spoke with three industry leaders who are strong advocates for pre-oiling in different parts of the market. They told us what the service can deliver to their customers, how they sell it to those who are unsure and what their process is.

Top decks

“We started offering pre-oiling as a service after we had customers coming back to us complaining of their decks cupping,” says Ryan McCarthy sales marketing manager at Coffs Harbour Hardwoods (CHH).

“We knew it wasn’t coming from us, as we take pride in our ability to dry timber correctly. Some were also getting a lot of surface checking, which showed they’d left their deck without any type of coating for far too long.”

McCarthy and his team talked with their customers about the importance of fully coating decking timbers before installation. “We explained that if timber is only coated on one side and is getting moisture ingress from underneath, then it will start to cup,” he says. “The top, which is copping all the sun, will dry out faster than the bottom and the timber will change dimension. So we’d be patiently saying ‘timber used externally should be coated on all sides along with the ends’ and then they’d get it to site and either forget to coat the bottom or find it inconvenient on-site.”

Accepting that some customers weren’t going to change, the CHH team looked for a solution. They had seen promotions regarding pre-coating machinery and set about doing their homework to find what would work for them and their customers.

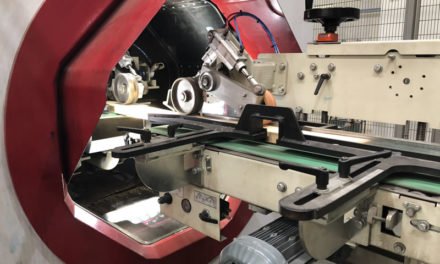

“We spoke with the guys from Ceetec in Melbourne and they recommended their Ceetec A250 machine,” McCarthy says. “We decided to purchase the machine, so we could offer our customers the added protection that pre-coating timber provides.”

The response was positive from early on, especially from local customers who could see the product at CHH. “We could explain to them that if they were going to spend good money on putting down a nice hardwood deck then they should also invest in good coatings and good fixings,” says McCarthy.

“For those who look at the small extra cost and ask ‘Do I need it?’, we can make a very good case for pre-coating. The timber arrives onsite already encapsulated in oil. This saves them time and money – we can put it through our pre-coating machine a lot faster than they can do it onsite and at a lower labour cost. On some building sites, the room to do it just isn’t there.

“It also protects the surface of the deck while the building is going on. As we found from the cupping complaints, decks are often left uncoated until the job is complete, which can be weeks or months. Dust and dirt is driven into the bare timber by the build team walking over it and water soaks in. If it’s pre-coated, then you just need a quick wash-down with a deck preparation product, a final oil and it’s ready for the homeowner.”

The choice of oils on offer was another research project. Eventually CHH decided to go with Intergrain’s Universal Timber Oil, because it is an open system that is compatible with most other products on the market, so customers could choose what they wanted to use on top, and Intergrain has a relationship with Ceetec.

“We’re still using the same product and machine today and found that both of them are easy to use,” McCarthy says. “Helpfully for us, the timber can be wet-stacked back into the packs after oiling, without the need for drying racks.

“The only thing we’ve had to tweak is that we found that the timber becomes slippery when coated, so we had to put a paper backing on our trolleys to stop the oil getting on the tynes of our forklifts.”

Massive effects

At the other end of the size spectrum, national business development manager Daniel Wright and the team at Australian Sustainable Hardwoods (ASH) use pre-oiling for their mass timber systems as a primer.

“Our laminated boards are produced in some pretty large sections, and they’re connected to other large laminated sections with precise, concealed connections,” Wright says. “Here in Melbourne, you might be installing them anywhere from today, which is wet, windy and cold, through to summer conditions where it’s 40 degrees and very dry. Large sections of glulam can take on moisture and expand or lose moisture and shrink. The result can be little checks, misalignment issues, even mould. Pre-coating gives the builder a little bit of peace of mind and can protect the timber from some of that expansion and contraction where it’s exposed to weather. It’s not perfect, but it’s a bit of insurance.”

The ASH team also opted for Universal Timber Oil as their main product. “We use it in the Clear almost exclusively,” says Wright. “It’s an effective primer for many of the other Dulux, Cabots and Intergrain products, it looks good and it performs well at preventing a little bit of moisture take up and loss. Add to that, it’s easy to apply, it’s local and, importantly because we’re a big production factory line, it can be wet stacked. We can apply the coating and then pack it, we don’t have to wait for it to dry.”

With members weighing up to 3T, and some other oils requiring overnight or several days of curing time, this saves a serious amount of time and space. ASH uses a roll-on or wipe-on application, due to the size and lack of uniformity in their product. The pre-oiling is done in the same finishing shed as the sanding, polishing and other touch-ups, including pre-attaching connections. The finishing team hand-apply the oil, flip the member to coat the other side, then wrap, pack and stack, ready for delivery.

“For our builder clients, protection during construction is front of mind,” Wright says. “We offer two solutions. One of them is a vapour-permeable wrap for each member, which can stay wrapped during construction, but then they have to pull the wrap back to make connections and remove it if they’re putting flooring on top of the beams.

“So it’s a lot of extra work for the installers and if water gets trapped inside the plastic, it can actually have an adverse effect. The other solution is the pre-coating. Even though it’s three times the price upfront, the end result is so much better and the labour costs so much less than the wrap that I’d say 90% of these jobs push us towards priming because of the ease on site.”

Successful screening

“We make a prefab panel product that needs oiling, because it’s going to be exposed to the elements” says Fergus Forbes, director of Kosny Timber. “In the past, some of our customers chose to oil it themselves, but a lot of the time, we were oiling for them. And in those days, we were spraying panels in our factory, which was an awful process. There were so many fumes and plumes of oil in the room. It was unpleasant to work in.

“So we picked up a Ceetec machine from Dulux. And we haven’t looked back. It’s dramatically easier to work with.”

The change to a machine-based system has expanded Kosny’s pre-oiled offer to around 70% of the products they send out. “We always recommend pre-oiling to our customers,” Forbes says, “because it makes our products last longer. And pre-oiling prior to assembly is far superior to trying to oil something after you’ve put it together. It’s faster, more even and on all sides.

“It’s even more essential on some of the other lines we supply, like tongue and groove cladding. I tell customers that if it was my house, I would only ever put up

pre-oiled cladding. Because moisture always gets behind things. And you can’t coat it on the back later.”

Forbes looked at a range of oiling machines before deciding on the Ceetec. “There are two or three main models on the market and they all had different strengths,” he says. “When it came down to the final selection, the Ceetec was more expensive than one of the other models we were looking closely at, but it had other attributes we wanted, particularly its speed.

“The speed it runs at is excellent, perhaps three times faster than the alternative we were looking at, which translates directly into productivity for us.”

Because the Kosny team is only running one machine, they only offer one oil choice, Universal Timber Oil. “If you offer multiple products, you need to clean the machine between each,” Forbes says. “And that’s a bit of a task. It means time with the machine down and it wastes a lot of oil as you flush each different type through.

“The machine itself is very versatile, it can even be used for painting, but if we ever decide we want to introduce pre-painted products, we’ll buy an extra machine.”

Again, even though the pre-oiled product comes at a price premium, the benefits are clear to Forbes’ customers. “It gives our resellers more margin. So it’s an upsell for them as well,” he says.

“And for the end users, they see the twin benefits of the time savings for installation and the product being protected. We did a TV shoot last week, with our pre-oiled merbau panel. And we completely transformed someone’s backyard in just one day. Our team framed up a fence, then just screwed the panels up. And that was it. They’re already oiled, the whole job’s done. Move on to the next thing.

“For us, that was getting back to the factory, but for our customers, that might be two jobs in the time of one.”

For more, contact www.ash.com.au, www.coffshardwoods.com.au, www.kosnytimber.com.au or www.intergrain.com.au