I once was an arsonist. I’m guessing I was about 11 or 12 years old and was part a group of school friends who stole some bullets from someone’s older brother. (Back in The late ‘70s I presume that it was perfectly normal for people to have bullets in the house).

Being normal boys of that age, that is without any sense of responsibility, we took the bullets into the bush and lit a fire in an attempt to set them off. We were at least sensible enough to withdraw behind trees to wait for the detonations.

Shortly, the awful consequences of our actions became apparent. The bullets didn’t go off. But we did start a bushfire!

In the absence of the bullets we could’ve easily gone and stamped it out but we were at least smart enough to realise that to do so could be the last thing we ever did! So, unwitting arsonists we became.

I’m telling you this now with an adult’s sense of retrospective shame. (Sorry Mum if you read this). However, I’m pretty sure that in the 1970s it was normal for boys to do similarly stupid and dangerous things. So we never felt that we had done a really bad thing, just that we might have really bad things done to us if we were caught.

To be caught would have incurred the standard punishment meted out in the 70s – thrashed to within an inch of our lives. Today’s boys caught something so stupid would not be touched. But on the other hand they would, at best, be labelled as delinquents and counselled or, at worst, put on the terrorism watch-list.

Enough, for a while, of my “skeletons”; now to a skeleton in the truss and frame industry’s closet.

There is a myth in some quarters that a truss can be cantilevered without further thought so long as the support is under the solid portion of the heel where top and bottom chords touch. That is rubbish! You may as well throw a pinch of salt over your shoulder for good luck as rely on this rule of thumb.

Experience with real world jobs and also laboratory testing of full scale trusses show that, depending on the loads and geometry, small cantilevers with the support under the heel-cut can cause problems, both of unwanted deflections and also additional stresses in the timber.

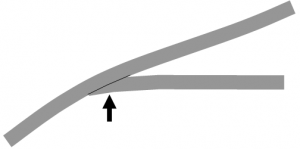

The diagram, although a little crude, is an output from my structural analysis package showing an exaggerated deflected shape of a cantilevered heel supported at the arrow.

A truss heel is the area of the truss with the highest forces anyway. Superimpose those forces on this cantilever geometry and nasty deflection of a few millimeters can occur between the support and the end of the heel. (You may be able to pick that up in the diagram).

The length of the overhang magnifies this deflection. If the overhang is, say, five times larger than the cantilever distance the deflection at the end of the overhang will be magnified by a factor of five also. This can spell trouble on site.

Without any strengthening, the timber stresses could result in a failure. The design must be addressed either by your truss software or by an engineered design. In broad terms though, depending upon span, loading, geometry and timber, the allowable cantilever may not be that large.

If you cannot get away with an unreinforced cantilever there are several options. A chock can help to share the stresses between the top and bottom chords. However, just because a support sits under a chock means nothing in itself. Additional stresses and deflections from the cantilever occur in the timber adjacent the chock, just as if the chock was never there. Once again we need a proper design.

A supplementary top chord will do the job although this isn’t cheap. Apparently in the USA it is relatively common to use a “slipper”, a length of timber about half the bottom chord panel length, nailplated to the bottom chord to reinforce the area of maximum stress over the support. I have never seen it done in Australia but I can envisage cases where it would be a neat and economical solution.

So, I hope the message is clear, cantilevering without doing the design checks is about as responsible as my wayward childhood!

And to finish the story, fortunately for us the ammunition situation was eventually resolved by a hail of detonations. The zing of bullets emphasised the danger of our plight but fortunately we survived. We rushed forward and managed to stamp the fire out. The final embers were mopped up, as you would expect from young boys, by peeing on them.

Were we ashamed? Did we tell our parents? Were there no more incidents? Not at chance. We had bush saved, lives saved, suburbs saved and hides saved – in our own immature minds we were heroes!

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News.

Phone: 02 4576 1555 Email: pauldavis@timbernews.com