Family-owned Gem Frame & Truss has kept growing throughout housing downturns by focusing on its relationships with builders and suppliers such as Framequip.

Talking with Malcolm Fraser, you wouldn’t know he’s based in a state with an officially contracting housing market. Gem Frame & Truss, the company he began in 2008 after decades in the building industry, has just invested in new machinery to handle its growing workload.

“We’re a medium-sized frame and truss team,” says Fraser. “We’ve got 27 employees working here and we manufacture about 500m of frame a day, mostly for residential housing.”

Loads are dispatched across the Greater Sydney region and as far north as Newcastle and south as Wollongong, though, as Fraser says, “Most of our work is out west. We don’t do a lot of commercial work anymore. It ties us up too much. We focus on project builders, plus one-off owner-builders.

“We do about four or five houses a day. So it’s a fair bit of work. We’ve got our own trucks and do all our own deliveries. When we bought the trucks about six years ago, it took away the problems we’d found relying on other people. Now we’re totally self-sufficient, which I find a lot easier.”

About seven years ago, Fraser bought two framers from Framequip, a family-owned business that focuses on machinery for the frame and truss industry. “Most of our work has been through one of these machines,” he says, “and with the amount we’ve pumped through it – six days a week, 12 hours a day – it was time to upgrade.”

Despite the business having grown since his first order, Fraser didn’t hesitate to go back to Framequip’s Rob Armour to place another order. “We went back to Rob because he builds good machines and they’re virtually maintenance free, which is what we like about them,” Fraser says.

Armour’s manufacturing system focuses on customisation and service. Fraser needed the framer to be a particular size to fit the line. His son Adam, who runs the yard, wanted to add some automation as well.

“We met with Rob at his workshop,” says Fraser, “and went through the list of things we wanted, and it was all no problem. It’s that personal service that you like to get. As another family business, I feel that Rob offers the same level of service and care that we offer: he’s virtually the same as us.”

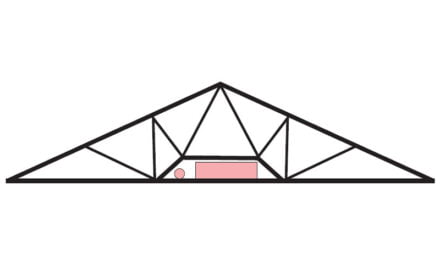

The resulting framer includes automatic loading, which has been popular among the staff. “My framer, Dave, absolutely loves it,” Fraser says. “He’s in his 40s and not getting any younger and he just said this has made his job so much easier.”

Trading on trust

Like all family businesses, Gem Frames has weathered a few ups and downs, but has succeeded thanks to good partners. As Fraser says, “We’ve built up a clientele of really good builders, who do a variety of popular domestic designs. They’ve been very loyal and this has meant we’ve been busy during the recent contractions.”

As well as frame and truss, Gem Frames supplies floor systems through a partnership with Wesbeam. “They also supply our LVL, which we use a lot of now because it’s lighter than hardwood and you get better lengths,” Fraser says. “We like the Australian product, and we get good support from them, and from our other big suppliers like John Cook & Sons. It makes a difference.”

Loyalty, support and self-sufficiency are Fraser’s keywords. “It all comes back to that family ethos,” says Fraser. “I’m the sole director, my eldest daughter, Nicole, manages the accounts, my son, Adam, controls the yard and production, my youngest daughter, Olivia, is the receptionist and my wife comes in every so often and does a bit of quoting and detailing. We’ve also got a good crew, which has made life so much easier for us.

“We’ve had a lot of the blokes here for years. Pat Leccese has been with us since day one. We look after our staff and we get that loyalty in return. It’s a good place to be.”

This practical and personal style of business means Gem Frames is well positioned now the outlook is improving. Fraser says, “We’re starting to see that turn in the industry and the way we’re set up now with the new machine, we’re comfortable we can do what we need to do to benefit.”

Gem Frames’ first Framequip machines lifted daily production rates from 170-200m on the previous framer to 450-500m over time. The new machine has already raised that by 10%. “The team like the ease of operation, and the fact these machines are pretty much unbreakable,” says Fraser.

Armour is also a national Airco distributor and manages Gem Frames’ fastener needs. He supplies fasteners and servicing to nailers and staplers when required, making life easier for Fraser and his team. “He does this for about 30 fabricators,” says Fraser, “so he’s an expert on the products.”

And, when things do go wrong, Fraser again sees the parallels between them: “Because we’re a family-run company, we do the hard yards. We offer close personal service and follow-up. Rob’s the same, he’s a phone call away. You talk to the man who owns the store directly.

“A lot of the time he just tells us ‘Do this,’ and we’re up and running again. That’s what my son likes about it. He says, ‘You know that if something goes wrong, it’s easily repaired.’”

For more significant repairs and maintenance, Armour makes house calls. “He wants to help,” says Fraser. “Because his business works the same way ours does, with reputation being so important. He knows he’s putting his machine in our factory and we need it to work, because we can’t afford to stop production. He keeps us going.”

For more, visit www.gemframes.com.au or www.framequip.com.au

Image: Automated loading in the new Framequip framing machine has made life easier for Gem Frame & Truss framer Dave Spiteri.