In the wake of the last, disastrous, fire season, materials are under close scrutiny. Clever options like FLAMEfixx use advanced technology to make timber safer in BAL-zones and more.

The Bushfire Royal Commission recently handed down its 1000-page final report. Alongside important recommendations regarding government action, better firefighting capacity and mitigation strategies, an entire chapter (19) is dedicated to land-use planning and building regulation.

In this chapter, the report specifically recommends “The Australian Building Codes Board, working with other bodies as appropriate, should: … conduct an evaluation as to whether the National Construction Code should be amended to specifically include, as an objective of the code, making buildings more resilient to natural hazards.”

Basically, we need buildings that are less likely to burn. For the timber industry, that’s a key challenge when it comes to the Australian market. Many people wrongly assume timber is always a fire risk.

Rather than argue the evidence of timber’s safety – because as we’ve seen in much of 2020, evidence often fails when it goes up against beliefs – FLAMEfixx has turned the problem around and used clever research to deliver a treated pine range that is proven to be significantly more fire resistant.

Finding the solution

FLAMEfixx was born in Auckland-based Wood Modification Technologies. Managing director Ron Moon had long envisioned an effective process that would lower fire risk in timber, helping builders in BAL-rated zones get the best of both fire safety and the speed and cost savings of timber construction.

“Bushfires play a big role in the Australian market,” he says, “so we knew there was a huge market opportunity.

“The holy grail for us was a total solution that combined outdoor protection to H3 and meeting AS 3959 (Construction of building in Bushfire prone areas) at BAL 29 rating.”

As it turned out, the solution was an actual solution. The full product name, FLAMEfixx dFx®, spells it out, with the d standing for durable wood preservative and Fx for proprietary inorganic metal fire retardant. Both are combined in a patented formula that is impregnated into sustainable, plantation-grown radiata pine using vacuum pressure.

“The market had been looking for something like this for about 50 years,” says Moon, “and around the world, no one had cracked it. It was complicated: the product formulation needed to be stable and able to be impregnated into timber, then achieve a process to fix the chemical into the timber and finally to meet the burn tests (combustion) Standard (AS 3837) for both peak and average heat release. We started our R&D period in 2014.”

It was not a perfectly straightforward process – “We spent the first three years working on a chemistry that in the end simply couldn’t deliver the outcomes,” says Moon. “But we really believed in what we were doing and those failures ultimately set us on the pathway to FLAMEfixx.

“There was definitely a spot of frustration and even despair in there, but we knew the idea itself was important, and every passing fire season emphasised the need,” he adds, ruefully, listing some of the many technical, engineering and chemical challenges that had to be solved before the team could successfully deliver a commercial product.

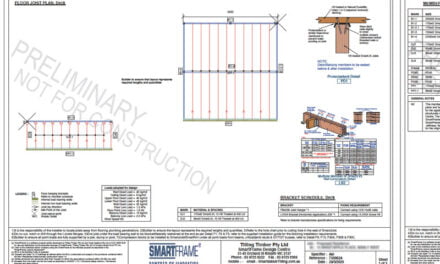

Finally, FLAMEfixx was ready for market and launched early this year with a range of screening, decking and structural timbers (joists and bearers).

“It means we can take FLAMEfixx treated pine timbers into bushfire-prone areas that were previously the domain of only non-timber products or expensive, naturally BAL 29-rated hardwoods,” Moon says. “This initial release will soon be extended into a wider range of products including cladding products (weatherboards, fascia, soffits) and glulam posts/beams that are particularly valuable in mid-rise construction, where fires are also a significant concern. We’re also working on expanding our offer, including into H4, BAL40 and USA Wildfires categories.”

Green and clean

One of the challenges for the FLAMEfixx development process was keeping the product as clean as possible. Moon and his team had seen the increasing restrictions put on treatments in sensitive applications, such as residential and childcare use, and wanted to reassure the marketplace the product would also be safe to live with day to day.

“We were clear from an early stage that there was an opportunity to introduce a very sustainable product,” Moon says. “We use sustainable radiata pine that’s plantation grown with a 28-30 year regenerative cycle. The H3 wood preservative is a water-based biocide and the flame retardant is an inorganic metal oxide. The Health, Safety and Environmental (HSE) profile of FLAMEfixx has no adverse environmental issues with clean air emissions and leaves a non-hazardous residual ash, so in the case of a fire, it’s safer for people evacuating or sheltering in place while the fire front passes, and also an easier clean-up.”

Thorough testing to ANZ Standards was carried out at BRANZ, an independent research organisation for the building industry (certification can be downloaded from the FLAMEfixx website), which proved the product withstood exposure up to BAL 29 conditions.

The choice of the initial launch range was made in response to evidence gathered after major fires in the past few decades. Common ignition zones include decks and other structures in the first 400mm above any horizontal surface. These are the areas where ember attacks are concentrated. In NSW, Rural Fire Service (RFS) policy affects the National Construction Code applying to these areas and requires a BAL 29-rated product, even in locations where the AS only requires BAL 12.5 or BAL 19.

As Moon says, “People in those BAL areas can now keep the traditional timber deck and build it out of FLAMEfixx pine that’s easy to use and still very affordable compared to options that satisfy BAL 29. FLAMEfixx meets all the standards and delivers that extra security.”

Moon and his team were also conscious of smoke inhalation, the number one cause of fire-related deaths. They knew that lowering the amount and toxicity of the smoke generated would help to increase survivability in bushfires and house fires.

“The flame retardant we used is an inorganic metal oxide that contains no hydrocarbons, so no black smoke is produced,” Moon says.

While the Australian Standard test isn’t reliant on smoke values for approval, American tests are. “Testing in the USA for wildfires requires both a Smoke Developed Index (SDI) and a Flame Spread Index (FSI) value in order to gain approval,” says Moon. “The FLAMEfixx smoke values are extremely low and consistently within the SDI 0-15 range and FSI 5-15 range. Untreated radiata pine SDI values average 115 and FSI 65.”

Market opportunities

R&D was complete in 2019 and an Australian market entry plan was designed with NSW and Victoria launches at the start of 2020, followed by the other states and territories.

“We’re still more or less following that plan,” Moon says, “but Covid has impacted production and distribution and consequently delayed some launch dates.”

Once again, the team has turned this setback into a plus, with the additional time being used to educate the marketplace about FLAMEfixx.

ITI Australia is the local distributor and Dane Kearns, national product manager ITI has been taking the message out. “There’s a sophisticated understanding about the need for this product out there,” he says.

“Recently we had a builder’s breakfast at Katoomba Mitre 10 in the Blue Mountains (NSW) and the builders we talked to had a great understanding of BAL ratings and the requirements set out by the RFS. Builders in these regional and rural areas do a lot of BAL-rated decks and houses, so being able to add this product to their core materials range is great for them.”

Moon says the sustainability of the timber and treatment have helped with marketing, but some drivers are more basic: “Builders really like the familiarity and ease of working with timber compared to cement, fibre cement or steel products in BAL-rated zones.”

The first launch range was decided partly because screening, decking and structural MGP10/F7 timbers represent a significant part of the Australian market in bushfire-affected areas. It was also partly because the AS 3959 testing regime using cone calorimetry provided a shorter (though not less difficult) path to market.

Now Moon and his team are working on the next chapter of the FLAMEfixx story. “We are moving into FLAMEfixx finger-jointed and laminated products, which include cladding (weatherboards, fascia, etc.) and glulam products for both BAL 29 and BAL 40, requiring assembly-based façade testing (AS 1530.8.1),” Moon says. Future developments may also include roundwood posts and poles, though H4 and H5 treatments would significantly increase the product costs.

“Right now,” Moon says, “FLAMEfixx has just commenced testing to a higher bushfire attack level rating, BAL40, via the Australian Standard Test (AS 1530.8.1) with Warrington Fire. We’re looking to gain BAL40 approval for external wall cladding systems, subflooring (joists and bearers) and decking, which will further increase the number of Australian homes that can choose to build safely with timber.”

For more, visit www.flamefixx.com.au