Never underestimate wind forces, especially when multiple lives are at risk.

As an engineer, perhaps the worst kind of failure that you worry about is a progressive collapse. It has happened with roof trusses, but outside the industry, one of the better-known examples is the 1968 Ronan Point disaster. A minor gas explosion blew out a load-bearing wall of a 22-storey tower block. The loss of support in one unit caused the collapse of one entire corner of the building, which killed four people and injured 17. It is the ‘domino effect’ on a grand scale.

In our modern codes, there is an explicit requirement for robustness, that is to avoid situations where the failure of a single component such as a window, a wall or a single truss web could lead to disproportionate failure of other elements, or even complete failure of the structure.

I investigated a house that was hit by what may have been a small tornado. A downstairs glass sliding door assembly was blown in. With no barrier to the wind, the inside of the building was pressurised like a windsock. That increased the internal wind pressure which caused the whole roof to take off down the street… and it took about 50% of the upstairs walls with it! But that wasn’t the end of it – the debris caused severe damage to five other houses.

It turns out that the 2.4m-wide glazing assembly that failed was held in place by only four nails through MDF architraves. So, for the lack of only a few nails and 30 seconds of labour by a window installer, a house was destroyed and five others were badly damaged.

There are two wind load codes in Australia: a simplified code for houses (AS4055) and one for any kind of structure (AS1170.2). This can include houses but definitely includes commercial and institutional buildings. There is a lot of commonality between them but there actually are a number of technical inconsistencies. Apparently, there is some disagreement between the boffins on the two code committees.

In simple terms, for non-cyclonic areas, AS4055 for houses assumes that windows, garage doors and the like do not blow in. A closed-building assumption gives us an internal pressure coefficient of 0.2. And that was also the value adopted by many designers in the past for industrial, commercial and institutional buildings. Remember that number!

It’s a pretty bold assumption because your typical garage door is not normally designed as a structural element and can blow in at the drop of a hat. And as my anecdote above demonstrates, windows are at the mercy of the window installer. And not every one of them is going to have a care factor.

Field surveys by James Cook University after major real-world wind events have found many instances of this sort of building failure where a blown in window or door opening exposes the interior of the building to the wind.

The code for buildings other than houses, AS1170.2 was changed in 2017 to say that:

“The full area of doors, including large access doors (e.g. roller doors), and windows that are normally closed, shall be considered to be openings, unless they are demonstrated to be capable of resisting the applied wind pressures … designers should consider the principles of ‘robustness’, i.e. to avoid situations where the failure of a single component such as a door or window could lead to consequent and disproportionate failure of other elements, or even complete failure of the structure.”

To use a lower wind pressure coefficient for non-house buildings you need a ‘structural assessment’ to determine that the doors and windows will not blow in. Except for major buildings, it is very likely that such an assessment won’t happen.

If we assume that large openings may occur in a storm, the wind pressure coefficient is 0.7 – that’s a 250% increase in internal pressure from what has been used in the past. (In cyclonic areas we already assume opening caused by debris impact.)

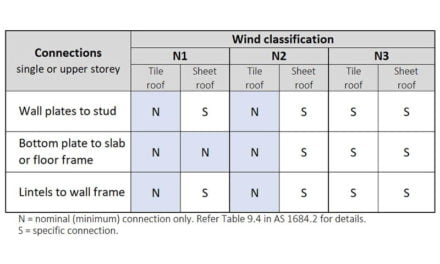

The practical consequence for you is that the wind load on your roof and wall frames can be different depending upon the building’s use. A building that looks like a house but is a nursing home or a day care building should be designed for a higher wind load than the house.

From a purely layman’s perspective that seems like a load of nonsense. Two identical buildings in the same location should have the same wind load.

Perhaps this discrepancy stems from the fact that the design for wind for houses is simplified and we are more concerned with robustness for the buildings that hold many people. Or perhaps this is because, to quote a famous saying from within the engineering profession: “Structural Engineering is the Art of moulding materials we do not wholly understand into shapes we cannot precisely analyse, so as to withstand forces we cannot really assess, in such a way that the community at large has no reason to suspect the extent of our ignorance!”

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News. Email: paul@projectxsolutions.com.au