When The Truss Co. planned its newest plant in Centralia, Washington, the renowned American firm turned to Western Australia’s Vekta to supply its machinery and design its system.

The conversation was meant to be about a PackFeeder – Vekta’s customisable, automatic timber infeed system. “The Truss Co. team had seen our marketing for the PackFeeder and rang up to enquire about it, in late 2019” says Ed Serrano, managing director of Vekta Advanced Automation.

The big American company is a leading truss manufacturer in the US Pacific Northwest and operates over eight locations with about 520 employees in total. A few years ago, they installed their first Razer saw from Vekta and had been happy with both the machine and the support they received from the Perth-based firm. So it wasn’t surprising when the initial PackFeeder inquiry became a more wide-ranging discussion about system opportunities.

“This new plant they were looking at opening came up,” says Serrano. “The conversation turned to the other systems we produce and things went from there.”

‘Things’ is classic Serrano understatement for a customised manufacturing solution that includes two Razer V5 saws with P3 precision printers, each saw fed automatically by its own PackFeeder; a buffered outfeed direct delivery system with approximately 75m of conveyor, with nine kickoff locations to service three primary jigs and one ancillary jig; custom software and a customised safety system including traffic management.

With this level of commitment, the relationship shifted from that of machinery supplier to partner/consultant. The Vekta team weighed all the information available to provide flexible solutions and options, while The Truss Co. team delivered transparency in its high level of early planning – along with significant levels of trust in its machinery partner. For both sides, the exercise has paid off handsomely.

“This isn’t the first full-plant installation that we’ve done,” Serrrano says, “but it is the first one where they’ve been happy to share the results widely so that the industry can see what’s possible. It’s a really positive story about what happens when a company centres both what they want to achieve in terms of output and how they want to support the workers doing those jobs. We’re really happy to be able to get the word out.”

Starting places

Of course, the journey from phone call to completed plant had a lot of steps along the way. A key component of success was that every one of those steps was guided by a clearly defined set of priorities.

Josh Wright, VP of manufacturing at The Truss Co., says the fact it was a new facility opened up what was possible. “With the current labour challenges we all face, it’s become apparent that automation is necessary to keep pace with demand.

“Outside of that, we find that highly automated plants improve our ability to hire because these plants provide a less physical and cleaner work environment.”

A lean staff head count was one of the main priorities for the Centralia plant: it was designed to run on a team of just 18. The others were a high production volume with minimal downtime. Serrano began his part of the process with tours of several Truss Co. facilities to understand their current processes and designed both the new systems and processes with the workforce at front of mind.

“This was the first of this sort of project for them,” Serrano says. “So they were really interested in what sort of options were available. Like everyone else, they’re having problems getting quality staff in, so anything they can do to reduce the required head count was an advantage to them.”

The top-level brief of what The Truss Co. wanted to achieve was clear: for Vekta it was a case of finding the best balance of the various paths to get there.

“Our starting points were the amount of cutting they needed, reducing head counts and making sure no one problem could take the entire operation down,” Serrano says. “We put together the on-paper perfect package and then we sat down with them and said, ‘All right, here’s the ultimate solution, how does that work with your budget?’ From that, we could see what could be simplified to come up with ways to achieve the same objectives at a budget everyone was happy with.”

Some of these simplifications included clever alternatives to full redundancies within the system. For example, in the ‘ultimate’ iteration, each of the saws had its own outfeed conveyor system. Serrano says, “To reduce the budget we made that a single conveyor system, but that meant we needed to come up with a way to ensure that both saws could run at full capacity. The saw should not be the bottleneck: you don’t want another piece of the equipment to slow down the overall performance of the system.

“We came up with an operating system that allowed the saws to kick off at their full speed and then a ‘buffering’ system that would sequence the components as they moved onto the conveyor line so that neither saw had to stop producing, both could just produce at their full capacity.”

In other cases, equipment redundancies were managed out of the system by having more onsite spares and training the staff in basic parts replacement.

Wright says, “Ed and his team really showed us that they could find a solution for most of our pain points by customising an equipment line to our building layout and delivering trusses in a more efficient manner to the build staff.

“The team at Vekta was able to open our eyes to material handling possibilities we didn’t know even existed. Ed and his team have been great to work with and the finished product has not only met but exceeded our expectations. With the minimal footprint of the PackFeeder, the accuracy, speed and reliability of the Razer V5, the speed and efficiency of the material conveyor system and the overall support – we are extremely pleased with the outcome.”

Securing jobs

One concern around industry automation is that it comes at the cost of jobs. But for fabricators, it’s often the opposite.

“Labour retention is a challenge in the US, just as in Australia,” says Wright, “and that is why many organisations are taking a more highly automated approach. Automation and technology tend to create a more attractive work environment for our younger staff as well as minimising the physical requirements necessary to perform the job, so we can retain our more veteran staff.

“Staffing in our industry has a been a challenge nation-wide for several years, so automation allows us to do more with less and, hopefully, attract a larger group of candidates for positions.”

One factor Serrano worked closely on with Wright and his team was driving buy-in from existing staff. He says, “What we’ve seen in the past is that, if you don’t do it properly, you can get a situation where people feel threatened and that automation means you’re trying to replace them, so you get resistance to it. But by working in partnership and involving as many of those key players as we can, right down to the operators at the saw and the jig level, we get that buy-in and they realise that it’s not about replacing them, it’s about getting everything to work more efficiently with them.

“These plants that we put systems into, they’re not looking to get rid of people, they’re having a hard time keeping the people they have. The problem is getting new staff in and that’s where that partnership working right from the top down to the bottom is really important.”

Specific Truss Co. requirements for the plant included minimising the repetitive actions operators were required to do in their work. Accordingly, the initial brief sought to reduce the walking and reaching for each jig operator during assembly.

“This meant we were delivering elements directly to the jigs in exactly the order they were wanted to build and in exactly the orientation, so no one had to spin boards around between the kickoff system and the assembly jigs,” Serrano says.

The buffering system that allowed the two saws to share the same outfeed also came into play here, so there was no need to choose between delivering the most efficient assembly to each jig and optimising timber use. “The way this system is set up, one saw can feed all four jigs or each saw can feed two and so forth, so we can balance these competing needs and ensure they still get the optimising results while maintaining the kickoff and orientation requirements at the jigs,” says Serrano.

“Operators want to use intelligent systems and the technology is there to do it. If it’s done properly, you get the buy-in from the employees on the floor.”

That same operator engagement helped in designing the safety planning that underlies the whole design, beyond just reducing the physical strain on workers. The jig and saw operators helped to identify major risks and solutions, including a full dust extraction system with a waste conveyor to automatically remove cut waste and fenced-off operating areas, both delineating truck traffic areas and keeping people out of the machinery movement zones.

Serrano says, “We find that as companies move towards automation, whether a full automation system like this or just going from pull saws to linear saws, it makes the job for all the operators safer and easier, which then makes them faster at producing.

“Here, the boards are loaded into the PackFeeder in one big bundle and then no one touches that board again until it’s placed into the jig. Even then the operators are set up so they’d typically walk 2m at most to get the board. The less manual intervention and the fewer touch points you have with packs of timber and lifting and spinning boards, the safer the operations. People can stay focused on their work and they’re not walking around forklifts or hunched over pushing a big trolley across the factory. It keeps them doing the interesting parts of their job and limits the dangerous ones.”

Growth potential

While most of the full-system installations Vekta has done have been in the US, interest has picked up in the Australian and New Zealand markets, too, as fabricators look for factory-wide efficiencies.

“We’re seeing it across the board, not only in the big truss companies dealing with the largest builders. A lot of smaller plants are starting to look down this path as well,” Serrano says. “It’s very much the case that every plant is different in what they’re trying to achieve, how they want to do it and the floor space they have, which makes operating as a partner rather than just as a supplier even more vital.“

An installation at Centralia scale obviously requires a decent amount of capital, but the benefits of customised solutions and having a machinery supplier that doubles as a production consultant are considerable at every scale, from basic customisations such as adapting what’s printed on boards or changing the order of the optimisation, through to custom software or packages of machinery designed to work in full concert.

“Just today I was talking to a small plant who’s looking at some of the systems similar to what we do in the US, so it’s great to see that,” says Serrano.

The Centralia project has done more than help The Truss Co. out-compete their rivals. For the Vekta engineering and installation teams, it’s live-tested the redundancies in their own processes as Covid saw borders suddenly close, re-open and then close again over the delivery and installation period (there was a complete contingency plan in case travel became impossible) and also shown the importance of good-faith cooperation, as The Truss Co. needed to provide extremely accurate measurements for the manufacturing process, then to have faith in Vekta’s in-house testing.

In the end, it went off without a hitch and the system is operating seamlessly with regular support and remote adjustments for further optimisation. Wright is more than just happy to be quoted on his appreciation of the results – as Serrano says: “We’re building a second system for Josh now and just this week they’ve placed an order for a third system for a third plant.”

As for Vekta’s own business, it’s been another year of substantive growth for the company. “It’s led to some very busy times!” Serrano says. “The growth hasn’t all come out of left field, this is definitely what we’ve been planning for, but we have had some unexpected disruptions, like Covid.

“Most of our challenges are things we already have plans or solutions for – we’re fixing our space constraints, we’re hiring more key staff with the right experience levels to help us with this new phase of the company. There’s a new and highly experienced general manager in the US to help us grow there and we’ve just hired a new, highly experienced production manager with a lot of lean manufacturing experience.

“We’re really adapting our existing systems and continuing what we were doing, just at an accelerated rate. No one would have thought we’d be seeing this boom in the economy 12 months ago, but you won’t catch me complaining, that’s for sure!”

For more, visit www.vekta.com.au and www.thetrussco.com

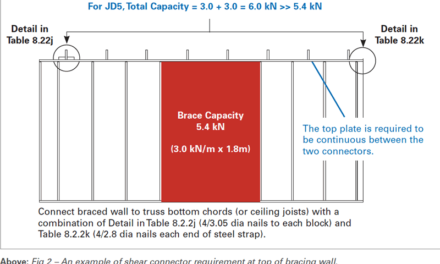

Image: The whole plant design began with an enquiry about Vekta’s PackFeeder – two ended up as part of the final fit out.