Fly me to the moon is a great song, but a terrible option for roofs. By Paul Davis

In late June, media reported that a rocket of unknown origin crashed into the moon. I have several theories: instinct suggests that it was Elon Musk landing his secretly designed spaceship at his lair on the far side of the moon. On the other hand, it may be Mr Squiggle heading home. Perhaps it is the Russians up to something, or perhaps it may be the rocket from the 1902 film by George Méliès, which crashed into the moon’s eye.

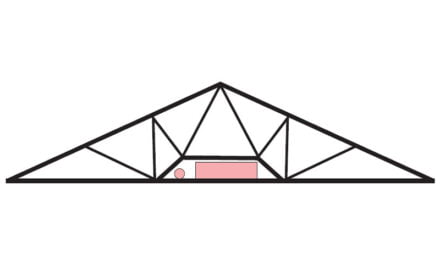

But I have another theory. Maybe it’s a roof. Last month I wrote about how free-standing roofs, where the wind is free to blow both over and under, are effectively a large wing. These structures can, for instance, be entry roofs, alfresco roofs or free-standing roofs such as picnic shelters, gazebos and cabanas. Even my own carport, as you can see in the photo above.

Once we have correctly assigned a wind load and designed the trusses, where do the uplift forces on the roof go to? How do we stop the roof taking off in a storm and, just maybe, hitting the moon?

In the case that the supporting structure is steel then typically that design is undertaken by an engineer. Typically, I would be designing a timber plate bolted to the top of the steelwork for you to tie down your trusses to. The fixings can then, as normal, be designed by your roof truss software. I hope other engineers are doing something similar. If the engineer is just doing a part-job and providing a beam size, then I suggest you push back and get the engineer to finish the job.

If you are using software to design a steel beam (effectively a lintel design and I believe some truss and frame packages do it) then I am afraid the design of this connection detail falls squarely on your shoulders. And so does the tie down of the steel beam itself. I suggest you seriously consider whether you want to take on that responsibility.

If you are sizing and supplying timber roof beams to support the trusses and the beam is supported on timber posts then I don’t see anybody else putting their hand up for the design. Fortunately, AS1684, the Residential timber Framed Construction Code, in Section 9 provides pre-calculated capacities for these fixings. The post base uplift capacities can then be looked up in suppliers’ literature.

But the tie down of the beams to brickwork or blockwork piers (or to masonry walls if the area under is partially enclosed) is one of those grey areas where it’s never clear who owns the design. By default, the brickie generally supplies some sort of strap or a block worker some sort of cast-in steel cleat. But typically, you will have designed the timber verandah beam and so know the beam uplift force at each end. Certainly, your average brickie is not going to have the mathematical or software smarts to do that calculation.

Even if you were to take on the task then there are no published capacities for tie down to brick piers. However, there are capacities to brick walls, so I have reinterpreted the standard and provide the following:

For a 30×0.8 galvanized strap, taken 900mm down the centre of a 350 square brick pier and embedded into the bed joint, the uplift capacity is 5kN. See Figure 6.3a of AS4773 for context.

This capacity is really quite low (about that of a triple grip) so it’s not a lot of use considering the wind uplift experienced by these sorts of wing-like ‘free’ roofs. The approach most likely to get a safe result is to run a booker rod down through the top of the timber beam, down through the brick pier and epoxy it into the slab/footings. (That is exactly what I did with the carport at my place.)

So, I come back to the point that you really need a skilled engineer’s input to design the supporting structure if it’s steel or brick construction. I know it may not be your job to engage that engineer, but at least you could flag the need to the builder – or to the engineer if the job already has one.

Now, you may think that my theories about the rocket that crashed on the moon are childish. But here’s a fact – five mice went to the moon on Apollo 17. Fe, Fi, Fo, Fum, and Phooey and three astronauts were the last Earthlings to travel to and orbit the Moon. Having considered all options, I am now convinced that the mystery rocket was crewed by the descendants of these mice – going back for more cheese!

Paul Davis is an independent structural engineer managing his own consulting firm Project X Solutions Pty Ltd. The views in this column are Paul’s and do not reflect the opinions of TimberTrader News. Phone: 02 4576 1555, Email: paul@projectxsolutions.com.au