Soudal delivers a clever new flooring adhesive and an even cleverer applicator that will help keep tradies safe and out of the physiotherapist’s clinic.

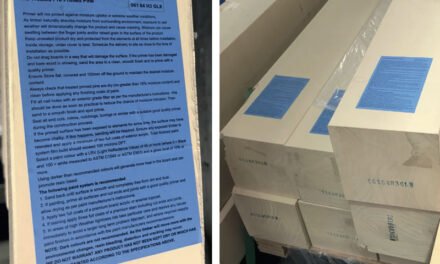

Soudal’s new Soudabond Subfloor Collapsing Gel Adhesive cuts application time over standard adhesives by 75%. If that was its only benefit, a lot of builders would already be reaching for the phone to order, but the company has delivered an even bigger set of improvements.

The high-strength, fast-curing polyurethane adhesive comes out as a foam, collapses down to a thick gel onto which the floorboard is laid, then foams up again to fill voids and gaps between joist and boards, without the air pockets that can lead to squeaks later.

There’s a 20-minute window between adhesive application and subfloor installation, and one can will yield approximately 150 linear metres at a bead width of 12mm – replacing at least 12 cartridges of construction adhesive.

As if the benefits to the flooring weren’t enough, Soudal has also delivered benefits to the floorer, with the traditional caulking gun replaced by a 1m-long applicator gun that means floorers can easily work from a standing position. The applicator gun delivers a precise bead that comes out 75% faster than the standard cartridge adhesive.

“The applicator gun isn’t just more comfortable for tradespeople to use,” says Scott Robinson, Soudal’s ANZ Region head of products, “it’s also safer, as they can reach out from the already-floored sections and deliver an accurate quantity of adhesive. They don’t need to step out onto joists and crouch over voids with a caulking gun.”

The can and gun can be left attached for use on the next job (within 14 days) or the applicator gun can be easily cleaned with Gun & Foam Cleaner, a fast-acting aerosol product that needs just a cloth and a bin to get the job done in a couple of minutes.

Soudabond does more than just save tradie back pain; solvent-free, it meets the stringent California Air Resources Board VOC regulations, providing a pleasanter working environment all round.

The adhesive takes 24 hours to fully cure and can be installed on wet or frozen timber with surface temperatures of -17°C to 35°C. The can itself should be kept between 5°C and 25°C, which can be managed with cool or warm water on extreme days.

Water-, mould- and mildew-resistant, it bonds all common types of subfloor to timber or metal joists or beams and, coupled with a mechanical tie-down system, represents a lasting solution that will avoid expensive callbacks.

With cost savings, time savings, and even space savings for cans over cartridges, the only people left unhappy will be the physios who won’t be fixing tradies’ backs.

For more, visit www.soudal.com.au